Highlights

Productivity

Increased production volume Daily 5 changeovers

Flexibility

Changeover time under 3 minutes Processes 6000+ different parts

Efficiency

Automatic vision quality inspection 24/7 operation

Usability

Wizard-guided HMI Intuitive operation

Initial Situation & Goals

Fischer Connectors develops and manufactures connectors for the most demanding applications. The globally operating company, headquartered in Saint-Prex near Lausanne, offers thousands of different products in its range and additionally develops customer-specific connection solutions.

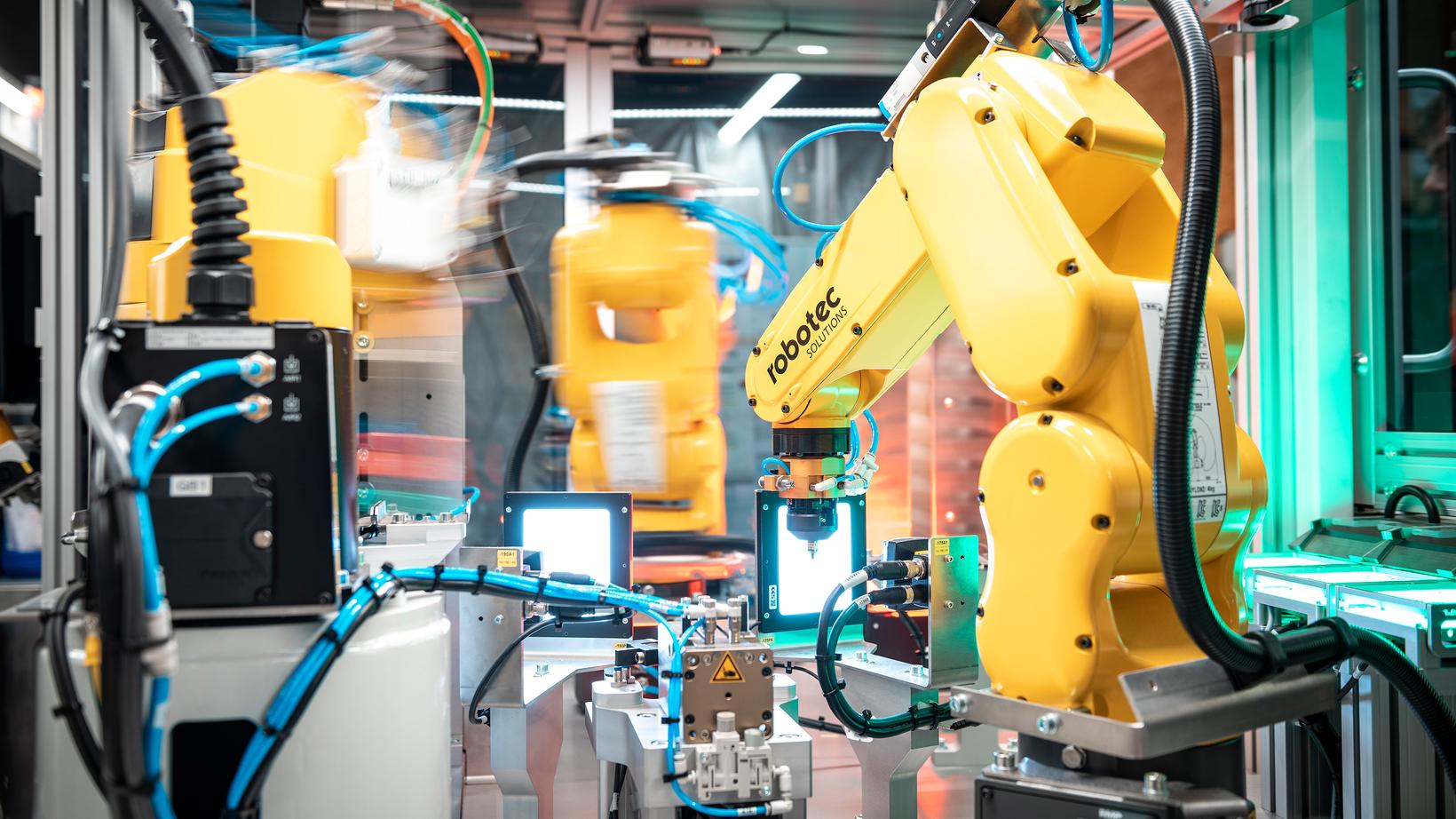

To achieve a production increase with increasing variety and constant quality, new assembly systems were needed that, in addition to the highest accuracy and reliability, also allow for quick, flexible changeovers. Thus, the systems at Fischer Connectors are changed over up to five times a day.

The Solution

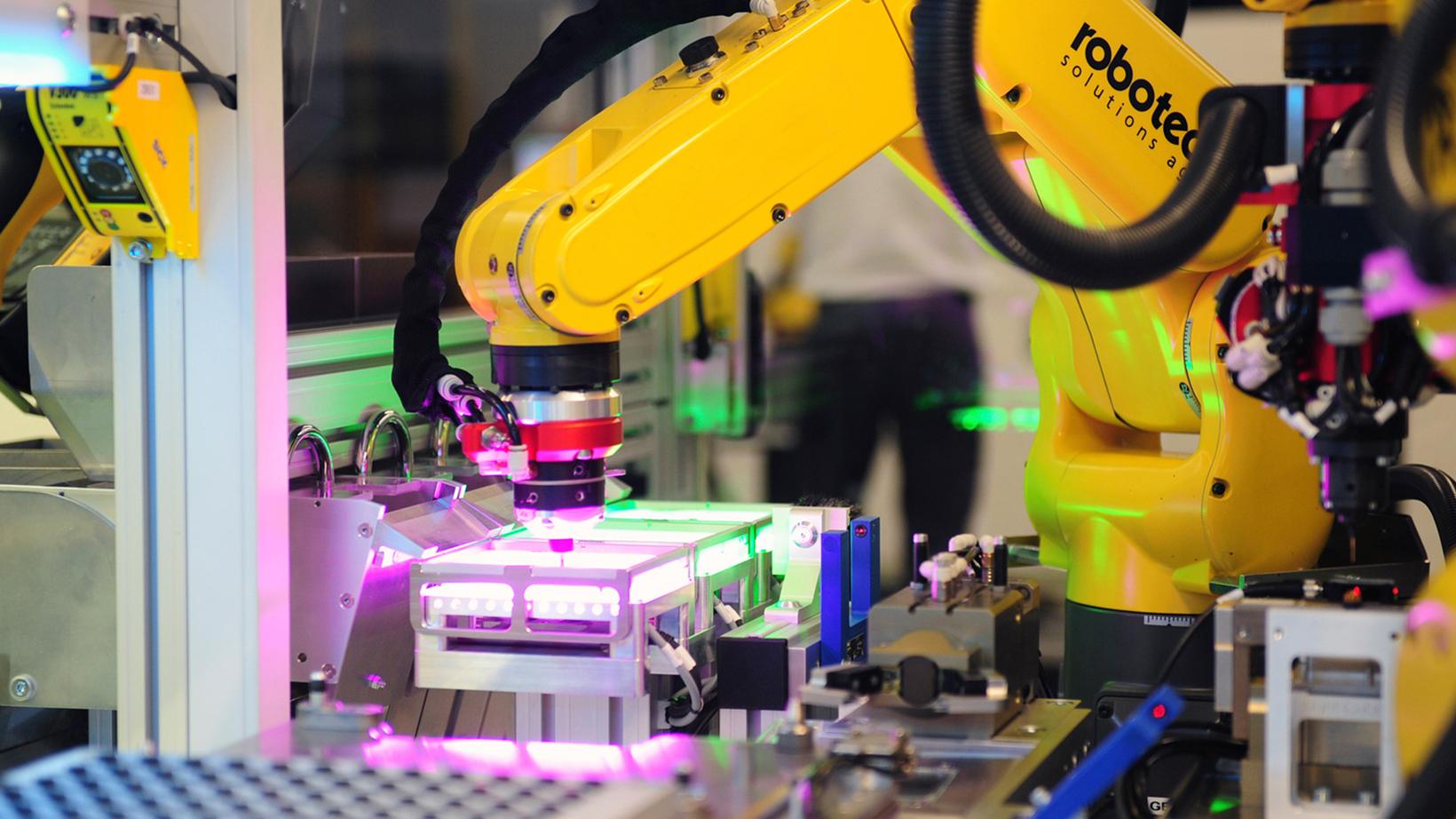

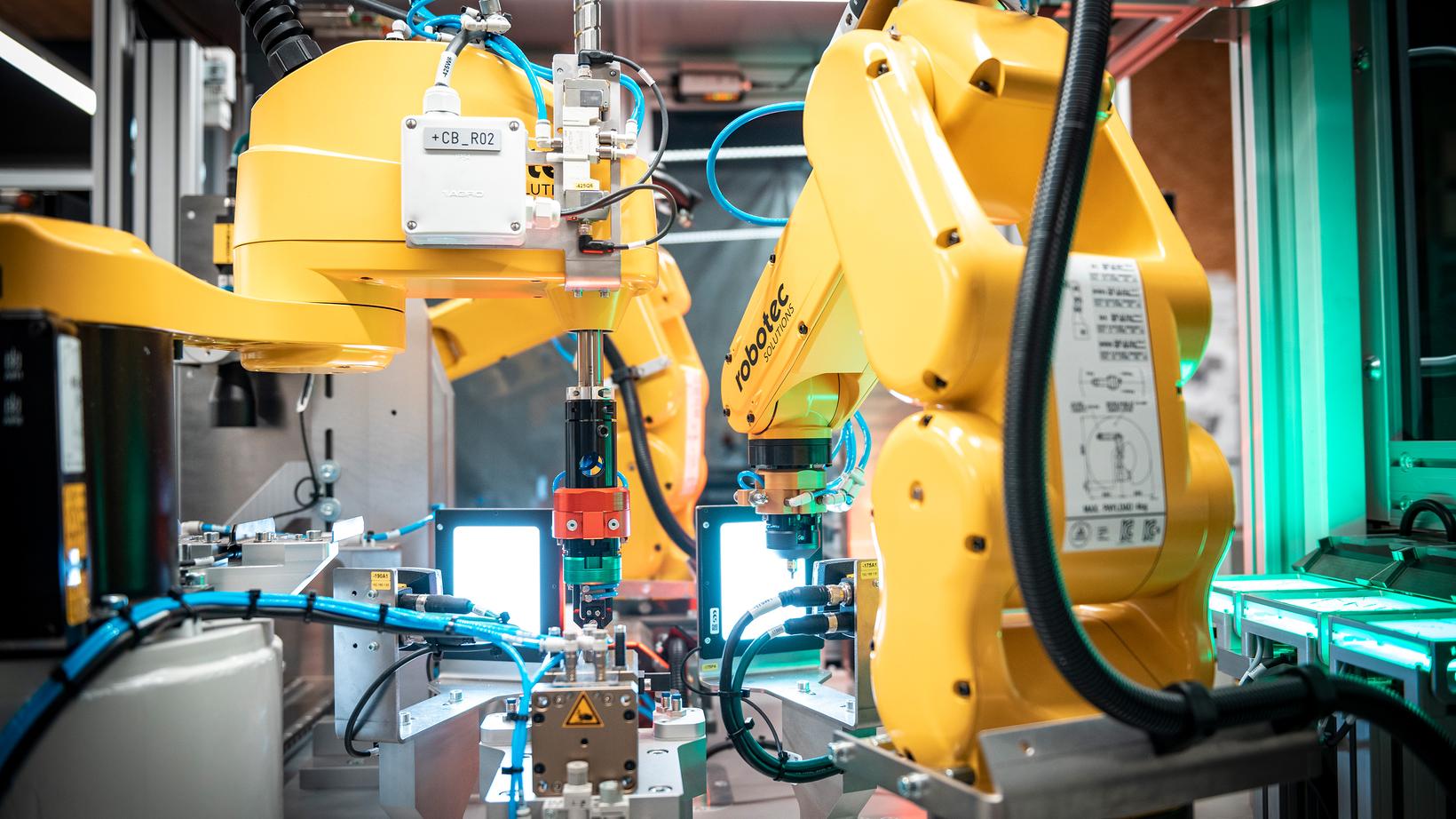

After analyzing the complex needs, we developed a custom state-of-the-art Robot Cell . The new robot-based assembly system features in-house Robotec feeders and Vision Systems with seven cameras, while high-precision axes ensure the highest accuracy.

The changeover takes less than 3 minutes – a few simple steps are enough. New connector types can be taught by the operators themselves via an intuitively operated, wizard-guided Human-Machine Interface (HMI).

Industry

Applications

Time for Your Project?

Let's talk about your automation project. I look forward to your inquiry via email or phone.

Nick Koch

CEO / Senior Automation Expert

The system remains one of the most complex solutions we have ever realized. It took about 12 months from development to production start.