Highlights

Productivity

Manufacturing cell with 7 robots, 1 cobot, and 2 mobile robots

Safety

Certified for manufacturing in a GMP C cleanroom

Efficiency

Automatic control through vision system with laser scanner

Usability

Simple, intuitive operation via central 24-inch touchscreen

Initial Situation & Goals

Flex Precision Plastics Solutions is part of the global corporation Flex, which operates with 250,000 employees at over 300 locations worldwide. At the Küssnacht site, the company produces pipette tips under cleanroom conditions (GMP C cleanroom).

The manufacturing of the so-called tips places the highest demands on production. Especially in this case: Within a few seconds, a large number of pipette tips should be relocated, assembled, inspected, and packaged.

In addition to the tight measurement tolerances for the pipette tips, traceability posed a major challenge. Furthermore, the system had to be designed to be as easy to operate as possible and require minimal maintenance and cleaning effort. All with the goal of high overall equipment effectiveness (OEE). This also included the automated and autonomous feeding and removal of the pipette tips.

The Solution

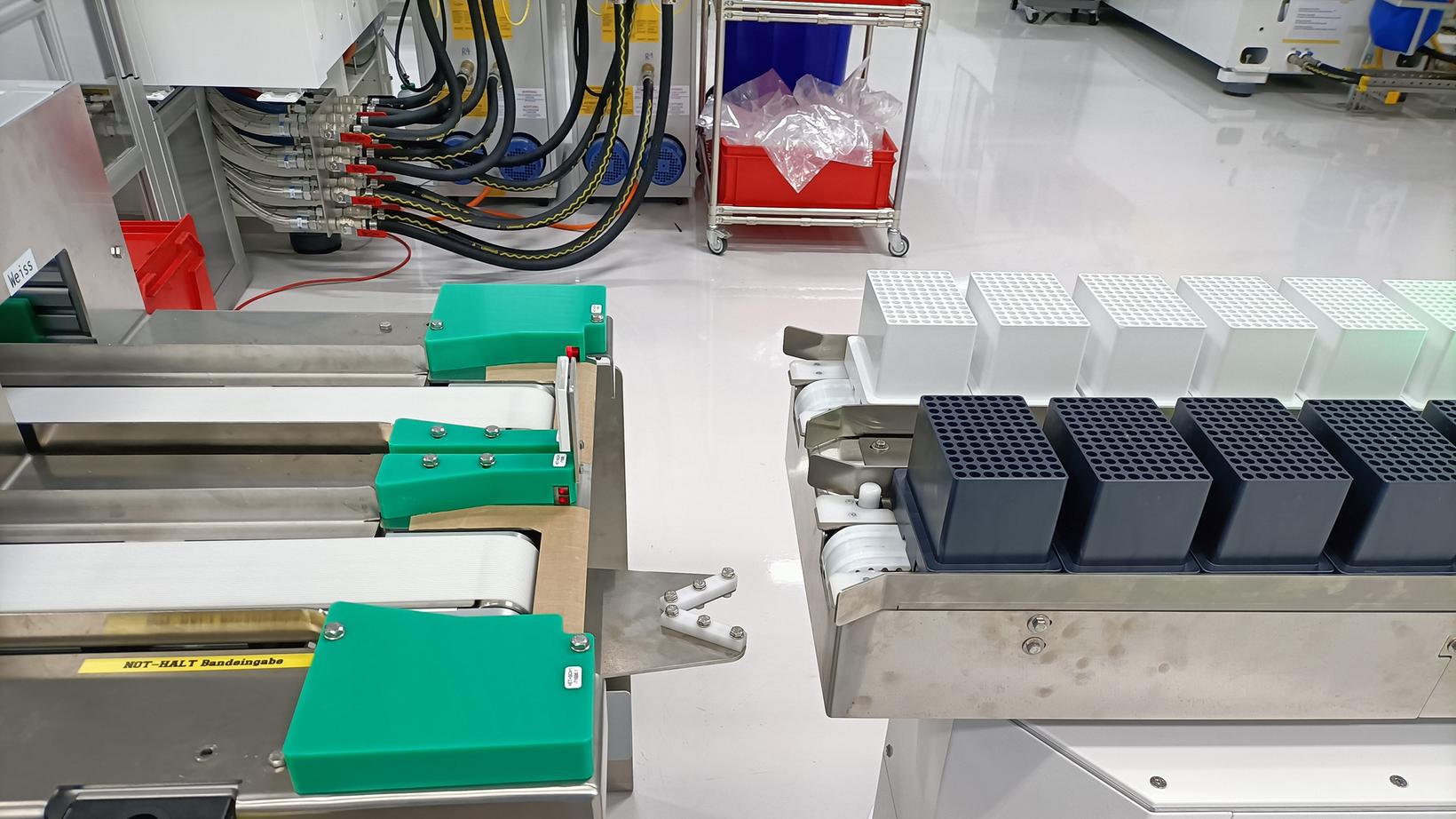

For the manufacturing system, we combined seven Stäubli Scara robots and three ACOPOStrak transport systems with laser scanners and Cognex image processing systems. Two autonomous mobile robots from OMRON, in conjunction with a FANUC cobot, take care of the feeding and removal.

The system simultaneously processes two types of pipette tips, which are then packaged together in a rack. The tips are placed on magnetic shuttles from the conveyor belt by a suction gripper. These receive information on which cavity is located in which position and pass through the following stations:

- Bottom-view inspection of the pipette tips

- Filter assembly

- Top-view inspection of the filter position

- Removal of defective parts

- Refilling with good parts

- Transfer to the sales rack

Finally, the sales rack is labeled, checked for completeness, and transported out of the system via the conveyor belt.

The 24-inch touchscreen enables intuitive operation of the system. This, along with clear user guidelines, minimizes operator errors and ensures high machine availability.

Industry

Applications

Time for your project?

Let's talk about your automation project. I look forward to your inquiry via email or phone.

Nick Koch

CEO / Senior Automation Expert

The system was validated according to the Robotec GMP standard, meets the highest quality standards, and impresses with easy cleaning. A modular design and intuitive operation further characterize the system.

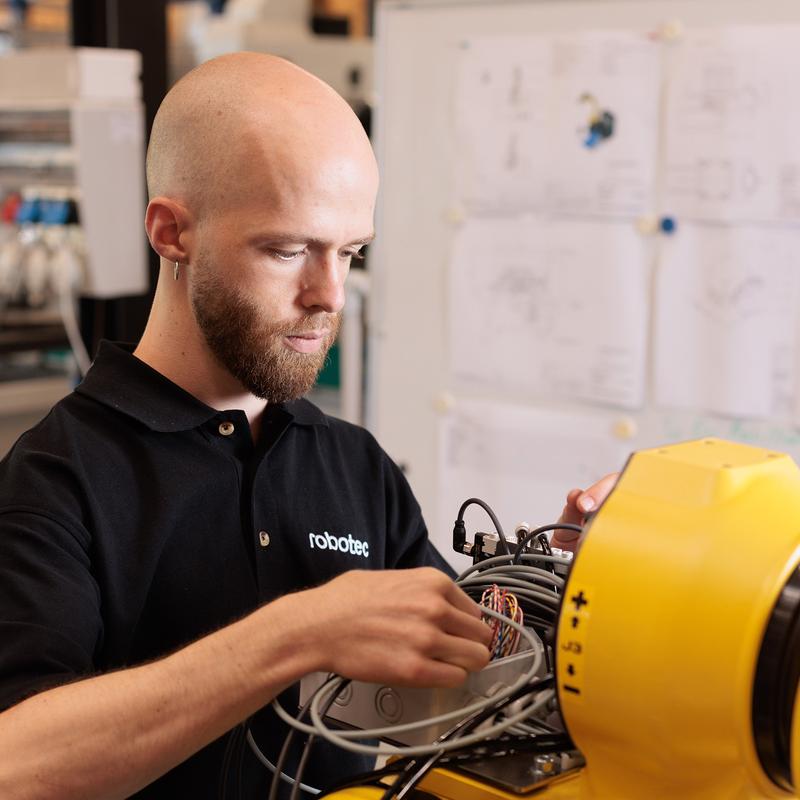

Robotec projectteam

Kevin Bossard

Project Management & Mechanical Engineering

Simon Rüdiger

Project Management & Software Engineering

Livio Stocker

Head of Production

Roman Müller

Project Management & Software Engineering

Danilo Kuzmanovic

Production

Pascal Balmer

Trainee in Mechanical Engineering

Denis Siegenthaler

Production

Yohannes Burki

Production

Lars Huwiler

Trainee in Automation Engineering