Highlights

Quality

More process reliability and increased product quality

Flexibility

Reliable detection of dirt and chips thanks to AI

Efficiency

Seamless integration into the manufacturing process

Usability

Simple, unambiguous operation

Initial Situation & Goals

For four generations, Nussbaum has been manufacturing and distributing fittings and building technology systems in the sanitary and heating sectors. There has been a close collaboration with Robotec for years.

To ensure quality, turned parts should undergo 100% surface inspection directly in production. A mobile inspection station without pneumatics (no compressed air connection needed) was required, which is easy to operate and reliably identifies the required quality features.

The main challenge was finding suitable optics to make all relevant zones visible in one image without movement. Since dirt and contamination from chips always look different, it quickly became clear that the vision system must be trained with AI for reliable error detection.

The operation of the system had to be designed as simple and error-proof as possible to support the operating personnel and prevent defective workpieces from passing the inspection.

The Solution

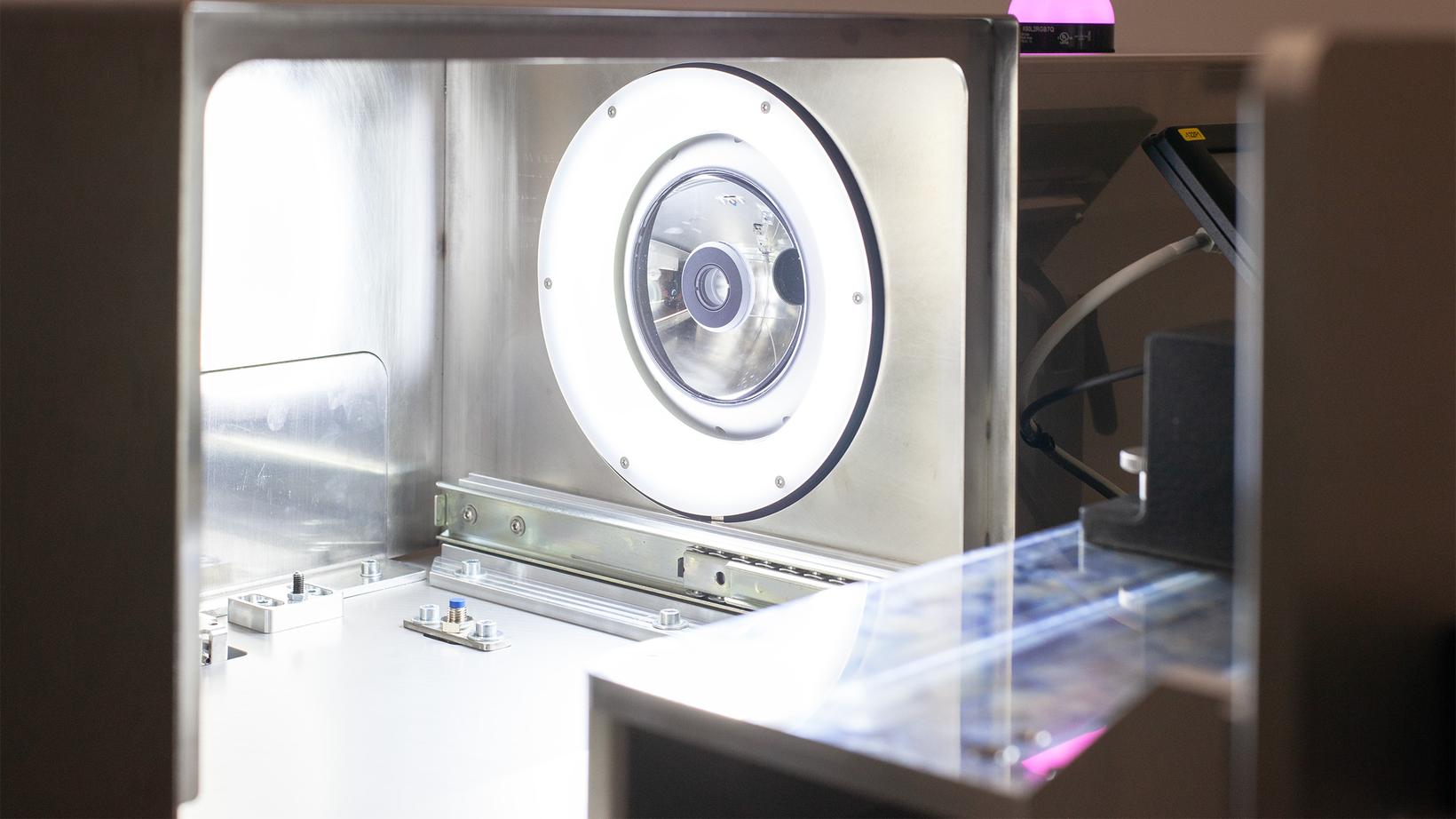

The system used is a manually operated, AI-supported inspection solution . A special optic allows the entire surface of a groove and the lateral surface to be unfolded, allowing surface inspection with just one Vision-System and without motion. This makes the cell energy-efficient, as it requires no pneumatic or electric drives.

The mobile inspection system is operated directly at the corresponding machine by production personnel. The unambiguous operation practically excludes the overlooking of defective workpieces.

Industry

Applications

Time for Your Project?

Let's talk about your automation project. I look forward to your inquiry via email or phone.

Nick Koch

CEO / Senior Automation Expert

The company Nussbaum has relied on our expertise in robot-based automation for years. Some of these solutions already incorporate vision systems (robot guidance). This gave Nussbaum the confidence that we can also implement complex stand-alone vision solutions.