Solutions for Your Industry

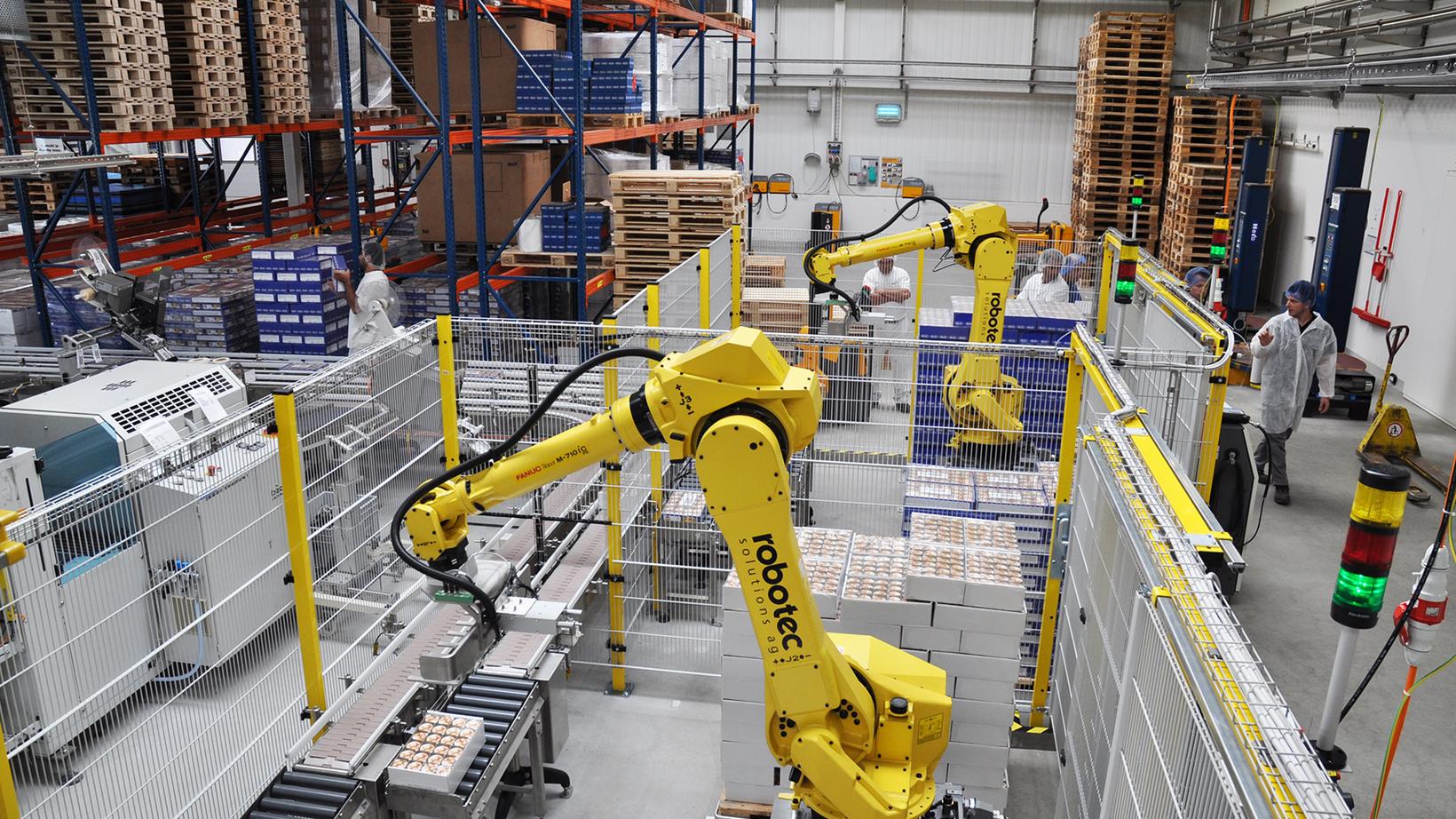

Automation in the Food Industry

Automate sensitive, repetitive, or inconsistent processes in food production. Increase consistency, productivity, and workplace safety. Discover interesting real-world cases.

The food industry places the highest demands on hygiene, traceability, and product safety. Even the smallest contaminations or temperature fluctuations can affect quality. Short shelf lives, frequent product changes, and variable batch sizes require flexible and quickly adaptable processes.

Strict legal requirements and regular audits require documented processes and seamless batch tracking. At the same time, moist, sticky, or cold environments make the permanent use of manual work steps difficult.

Advantages of Automation

- Automated handling enables shorter cycle times

- Hygiene thanks to CIP-capable systems (Cleaning-in-Place)

- Consistent product quality, reduced contamination risk

- Real-time monitoring for full traceability

- Relieving employees from repetitive tasks

- Avoiding ergonomically stressful activities

- Higher throughput rates in pre- and post-processing

Automation in Detail

From the first day, the robot worked flawlessly and was welcomed by our employees almost like a 'colleague'. Thanks to the enormous relief, we can now focus on other, more conceptual tasks.

Why Robotec

Our 5-Point Promise

Frequently Asked Questions (FAQ)

Your Contact Person