Solutions for Your Industry

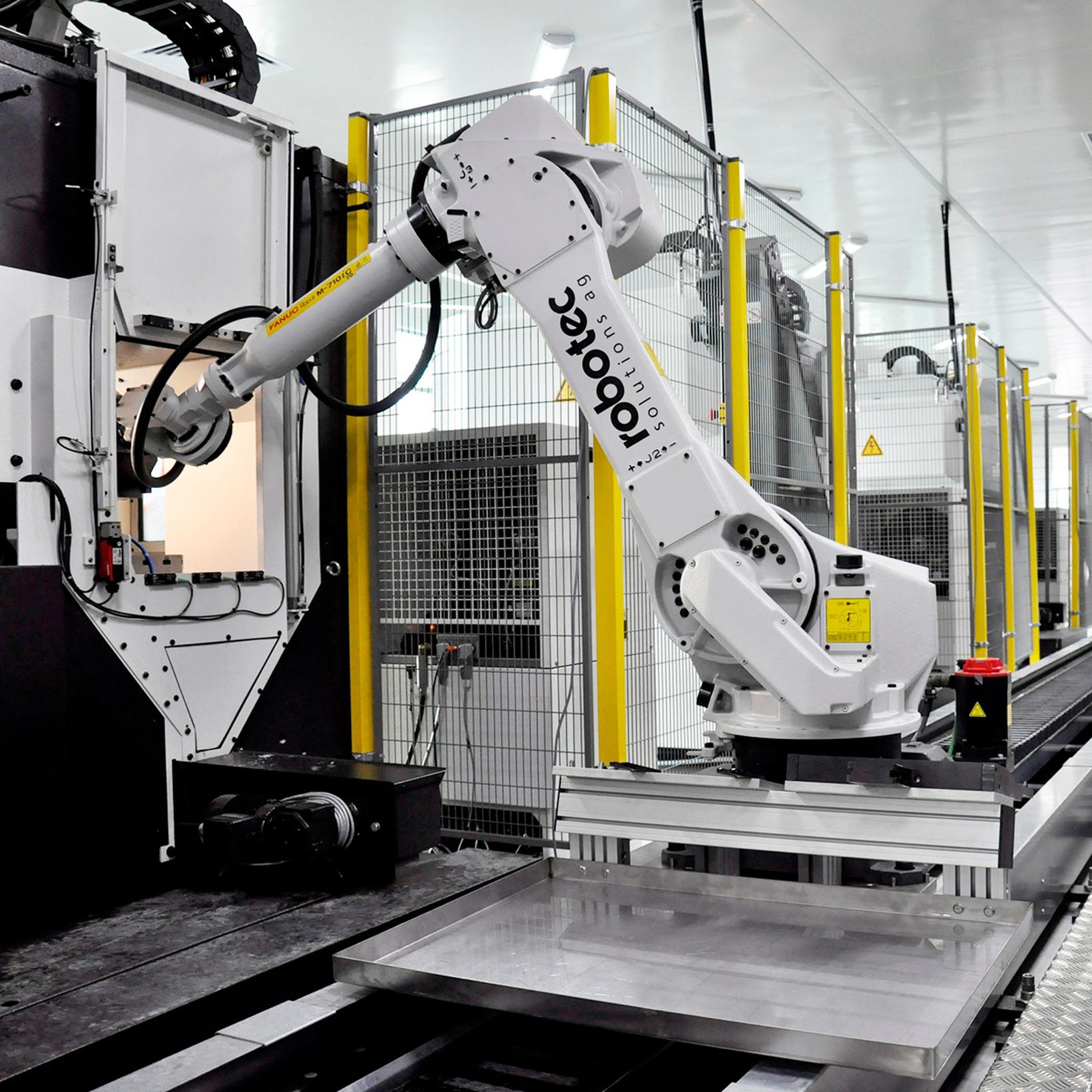

Automation in the Metal Industry

Metal processing is characterized by heavy components, demanding machine processes, and high productivity pressure. With our automation solutions, we relieve employees, increase efficiency, and ensure 24/7 operation.

In the metalworking industry, processes such as loading and unloading, CNC machining (e.g., milling, turning, grinding), or surface treatments dominate. These are not only labor-intensive but also often pose health risks. The shortage of skilled workers further exacerbates the situation, especially during night shifts or weekends, where constant productivity is required.

At the same time, the demand for flexible solutions is increasing, as smaller batch sizes or changing part types need to be processed. Automated bulk-feeding systems and conveyor tracking enable efficient handling of large quantities and provide machines with material around the clock.

Safety-related aspects also play a central role: where hot, heavy, or rotating machines are in use, automation helps keep people out of danger zones. The goal is always to maximize productivity—reliably, safely, and scalably.

Advantages of Automation

- Safe handling of large and heavy parts, even under harsh conditions

- Automated loading and unloading of machines like CNC, milling, turning, or grinding

- Efficient bulk-feeding and conveyor-tracking solutions for continuous supply

- Relief for employees from unhealthy, dangerous, or monotonous tasks

- 24/7 operation even without staff presence—ideal for night and weekend shifts

- High flexibility with small batch sizes and frequently changing workpiece types

- Increase in productivity with consistent process quality

- Safety gains through automation of risk-prone work zones

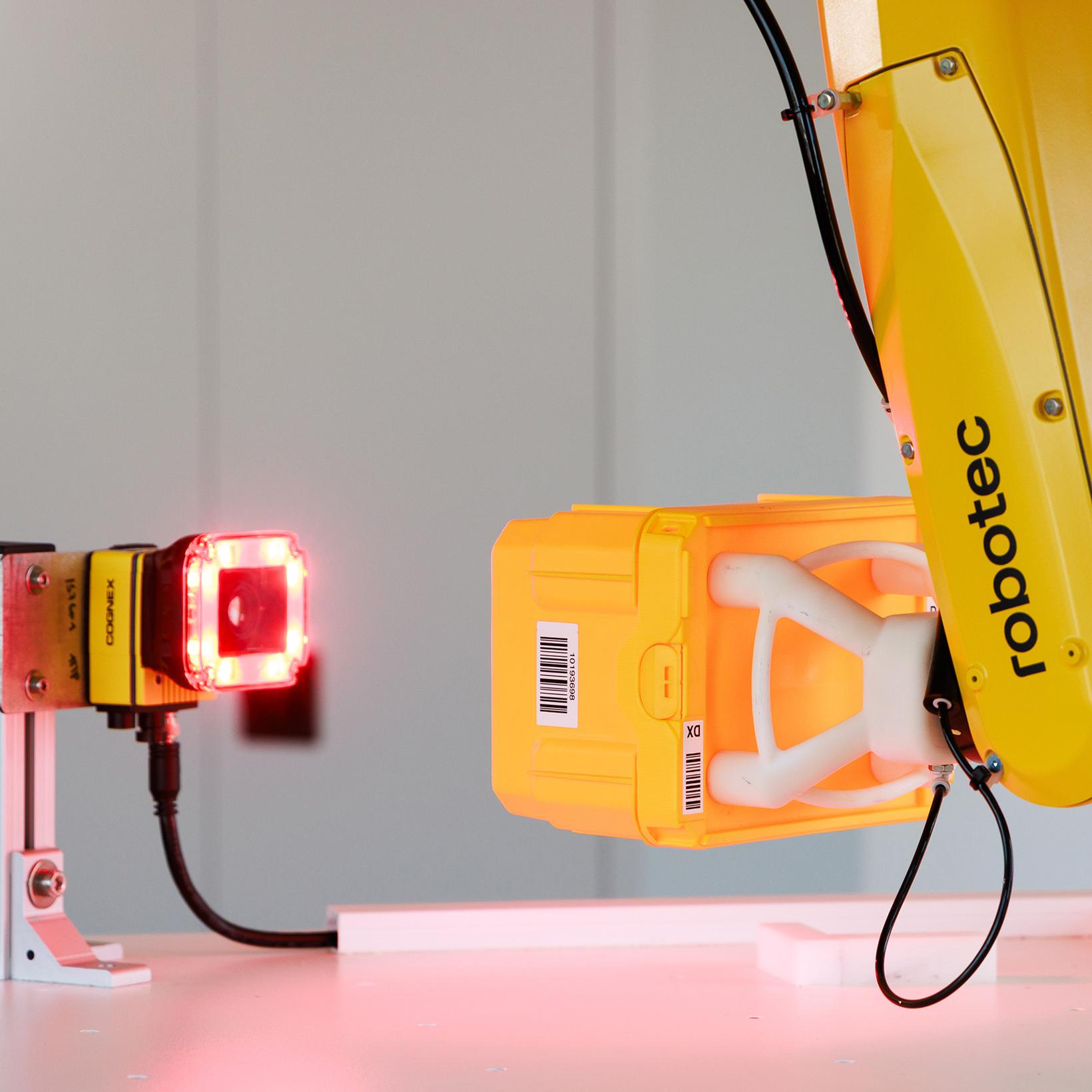

Scan at the dentist on Monday, insert the newly manufactured crown by Wednesday. This is made possible by the robot-based, intelligent networking of multiple CNC machines.

Cases

Customer Projects from the Industry

Why Robotec

Our 5-Point Promise

Frequently Asked Questions (FAQ)

Your Contact Person