Automate CNC handling in luxury goods and watch manufacturing with Robotec. Our customized robotic solutions ensure the autonomous loading and unloading of machines like the FANUC Robodrill, enabling more precise and efficient production – for excellence without compromise.

The manufacturing of luxury goods – watches, jewelry, high-quality leather goods, or writing instruments – is characterized by the highest standards of quality and precision. Each product embodies exceptional craftsmanship but must also withstand modern industrial demands:

- Minimal dimensional tolerances when processing components.

- Absolute reliability and repeatability of production processes.

- Flexibility to accommodate model variety and small series.

- Traceability and cleanliness, which are essential in sensitive environments.

Luxury companies must therefore balance artisanal tradition with technological capability to remain competitive in the face of increasing product complexity and ever-shorter market introduction times.

Craftsmanship and Robots?

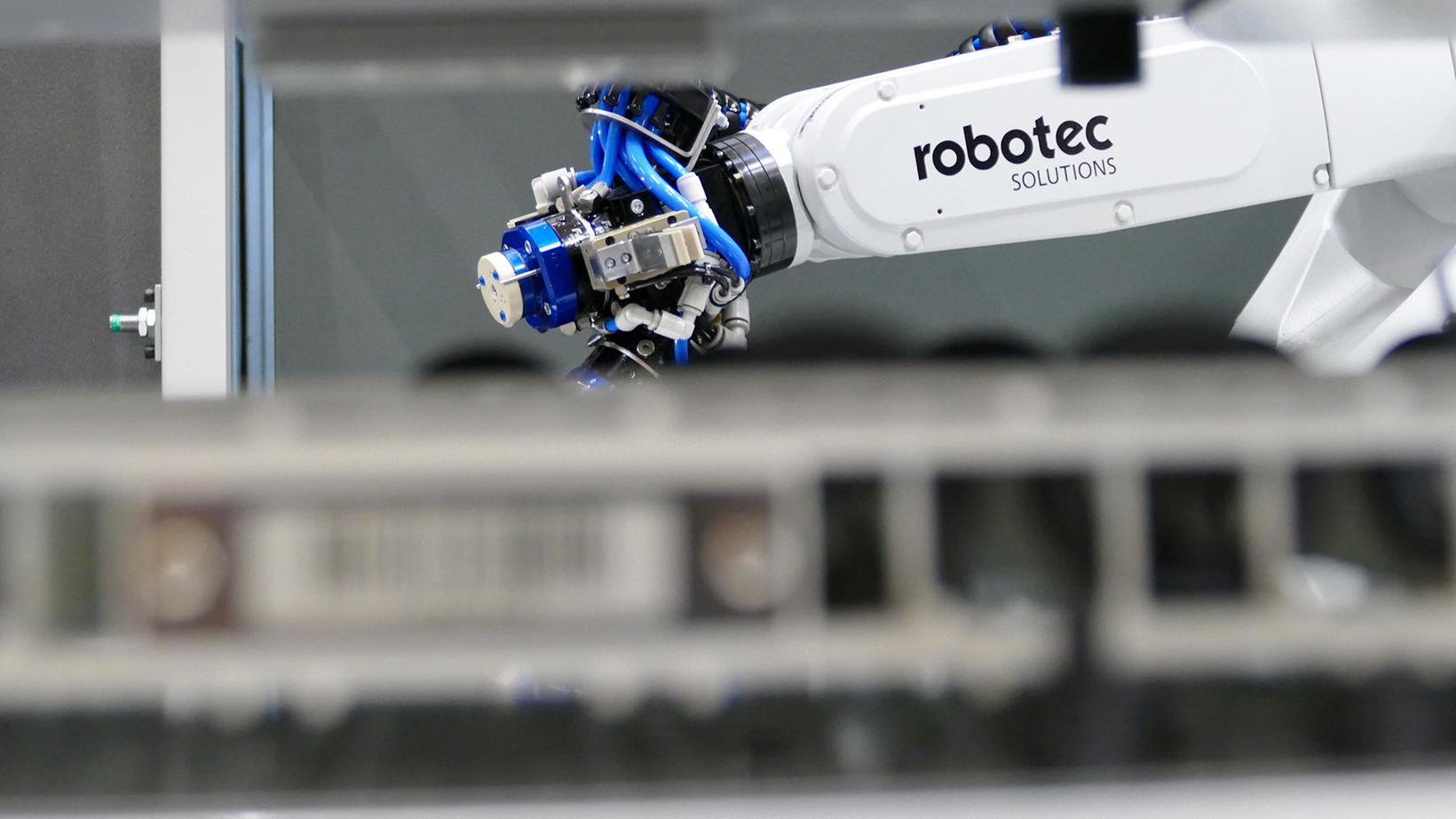

First of all: Robotization does not replace artisanal excellence – it complements it. Because Robotic solutions in luxury goods and watch manufacturing enable the automation of repetitive and time-consuming work steps. Qualified employees are thus relieved and can focus on more demanding tasks with higher added value. The advantages are manifold:

- Consistency of processes and reduction of human errors.

- Increased productivity through continuously operating cells.

- Improved safety by reducing manual handling.

- Flexibility in adapting to different references and small series.

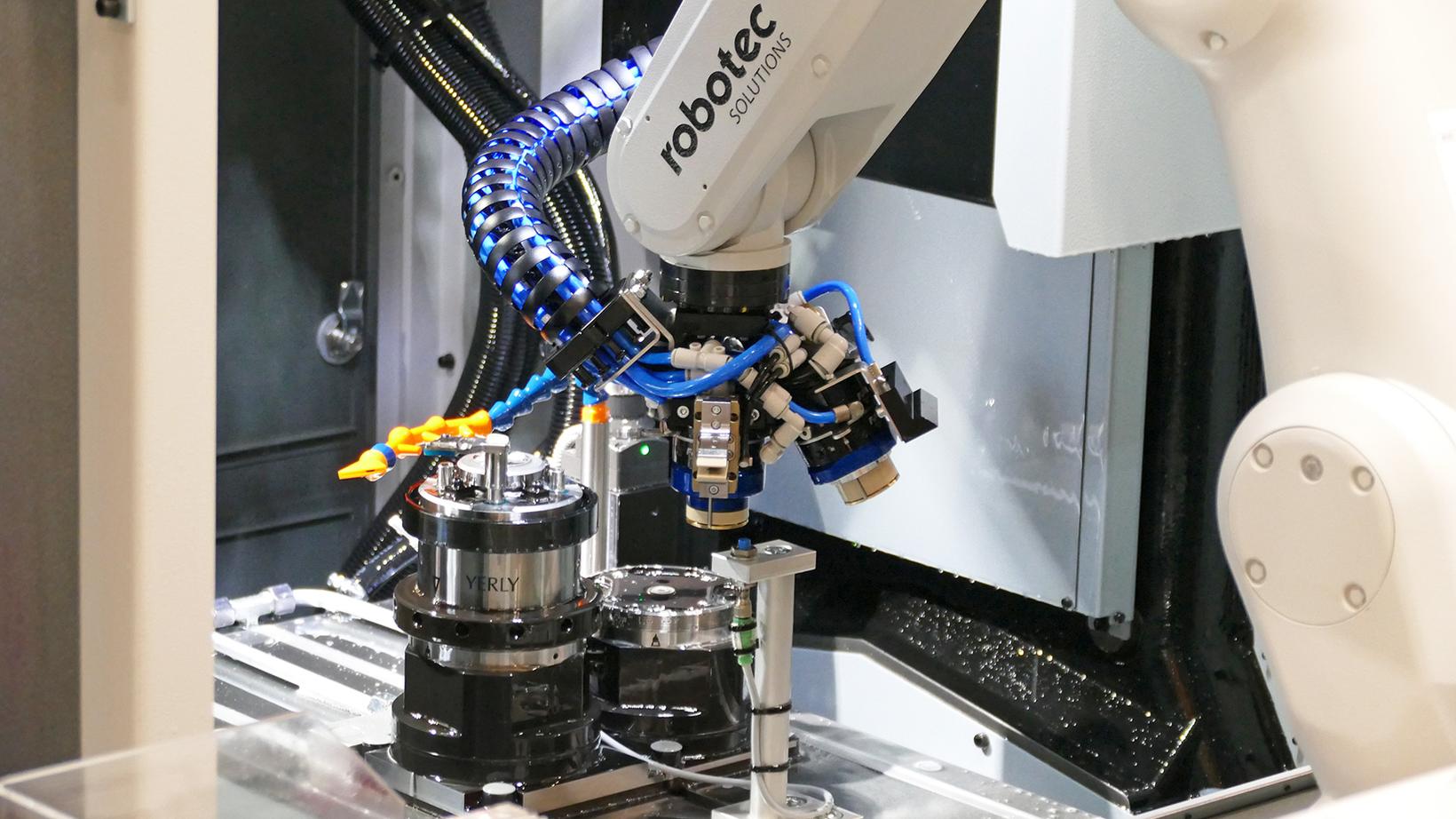

Loading and Unloading CNC Machines

CNC machines are the heart of manufacturing in the watch and jewelry industry. They process complex components with utmost precision, and their productivity directly depends on the efficiency of loading and unloading. Integration into a Robotic cell therefore offers numerous advantages:

- Optimized utilization of CNC machines thanks to fewer failures due to manual handling.

- Continuous operation, even at night or with reduced teams.

- Gentle and consistent handling of delicate parts thanks to suitable grippers.

- Automation of traceability by assigning each part to its production cycle through reading/writing codes or RFID chips.

The result: improved performance, consistent quality, and higher profitability of machine investments.

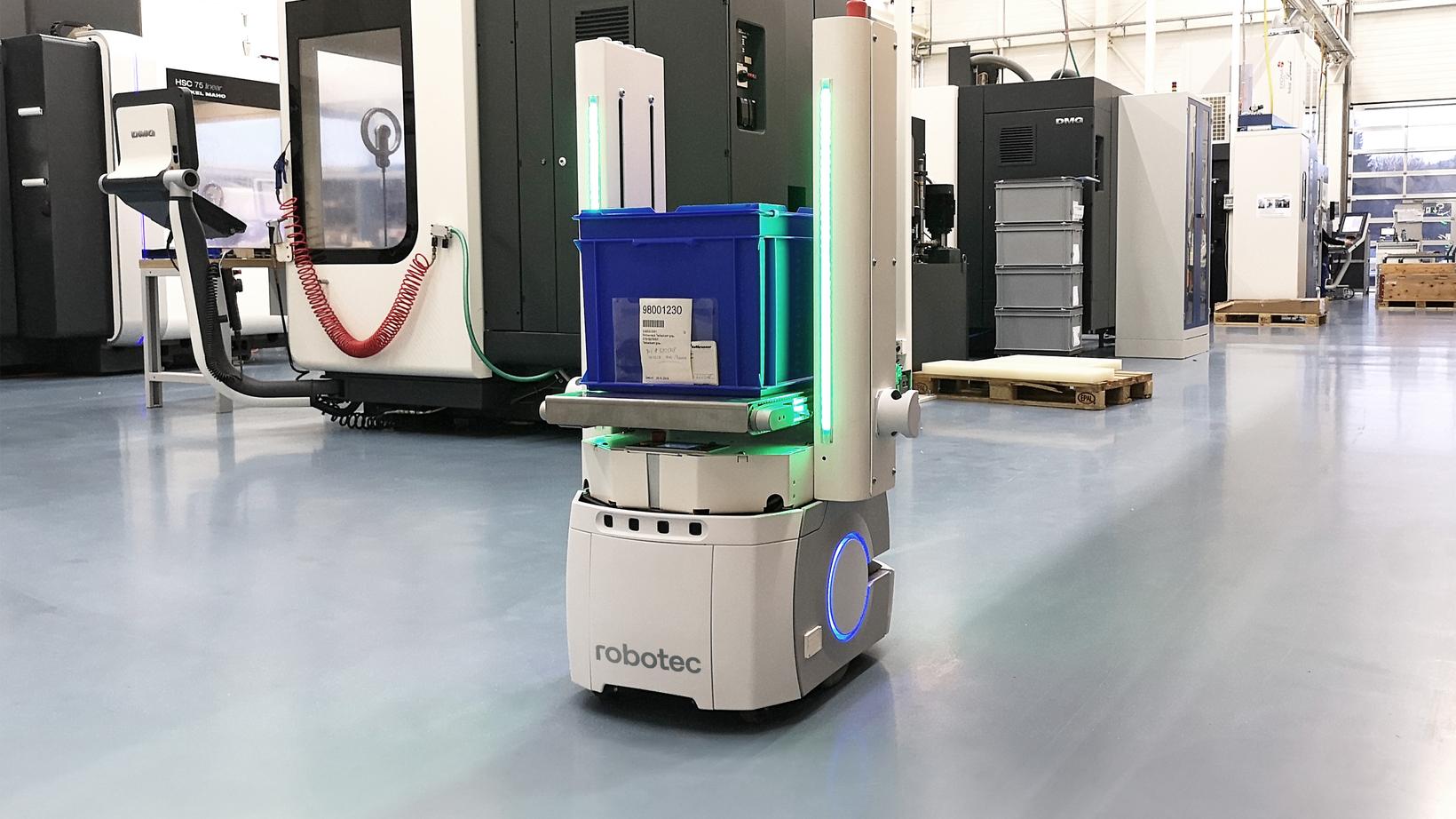

Intralogistics with Autonomous Mobile Robots (AMR)

In addition to manufacturing stations, the overall efficiency of production depends on well-organized intralogistics. In the luxury goods industry, where volumes are fragmented and series are often small, managing internal processes poses a real challenge. Robotic solutions with autonomous mobile robots (AMR) offer concrete solutions:

- Automated transport of components between manufacturing stations and storage.

- Uninterrupted supply of parts to production lines.

- Reduction of manual transport routes, which cause time losses and breakage risks.

- Digitization and traceability of flows for real-time management.

The result: Intralogistic automation ensures optimal synchronization between manufacturing stations, improves production responsiveness, and strengthens your company's competitiveness in the luxury segment.

Cases

Comparable Customer Projects

Robotization does not replace craftsmanship – it complements it. Robotic solutions enable the automation of repetitive and time-consuming work steps. Qualified employees are thus relieved and can focus on tasks with higher added value.

Discuss Your Project Now

Are you planning an automation project in the field of CNC machining? Or would you like to learn about the benefits of automation? Call me or send me an email to schedule an online appointment (Teams Call). I look forward to hearing from you.