Highlights

Productivity

24/7 assembly with high cycle rate

Flexibility

Automatic part recognition via vision system

Efficiency

Compact cell with small external dimensions

Usability

All-in-one: sorting, positioning, pressing, and controlling

Initial Situation & Goals

Actuators are ubiquitous in HVAC applications such as building climate control.

The Swiss high-tech plastic processor Wild & Küpfer needed a new, compact assembly system for the production of motor print carriers, where precise plastic parts from their own injection molding are assembled into modules. These consist of small electric motors, gears, and circuit boards.

A particular challenge was the recognition of these parts, which are delivered in cardboard boxes.

The Solution

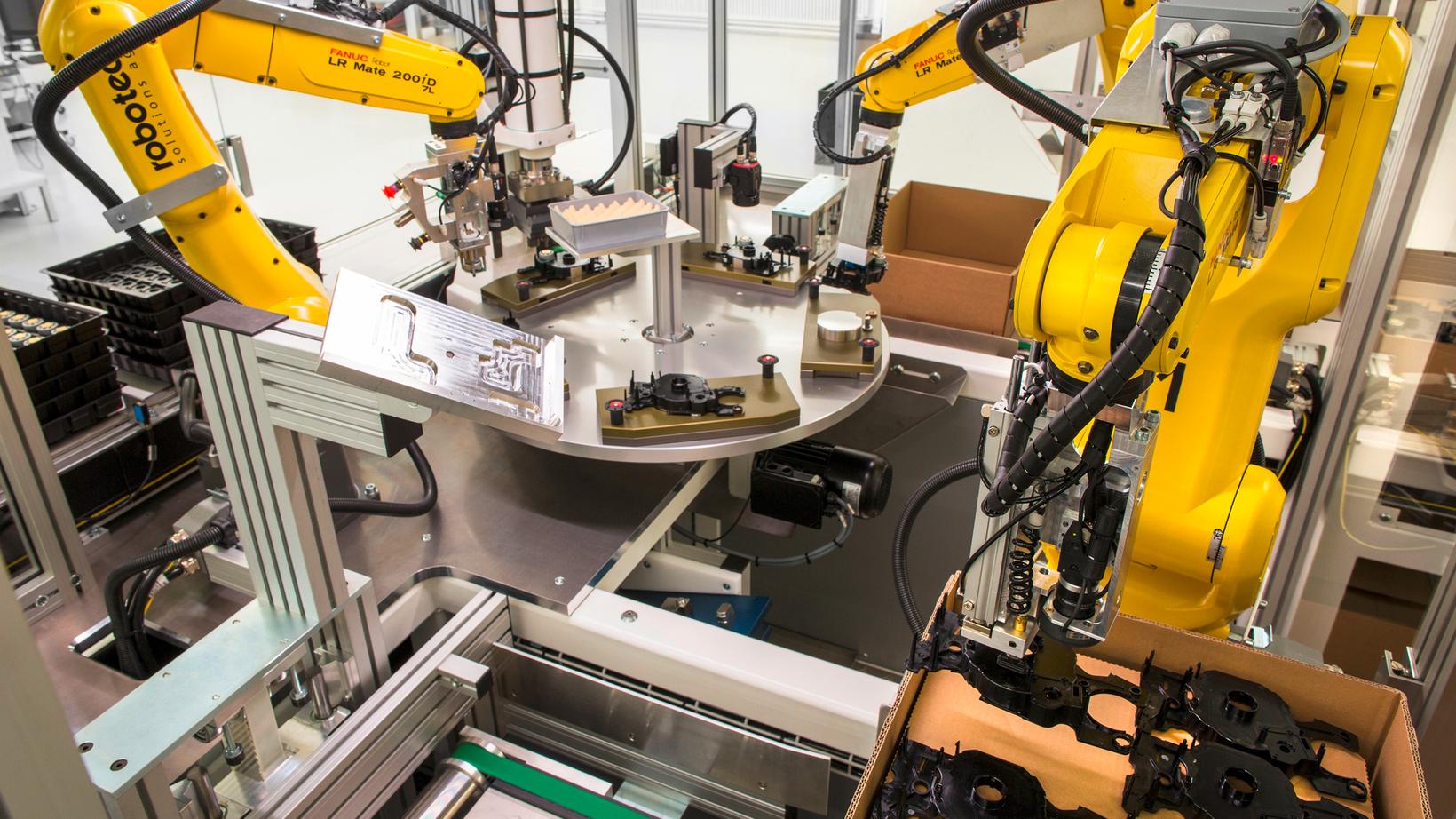

The centerpiece of the system is a compact Robot Cell with three long-arm 6-axis robots from FANUC. Using a Vision System , the parts in the cardboard boxes are recognized and then positioned on a rotary indexing table. There, fully automated assembly into modules takes place over several stations.

The robots perform sorting, positioning, pressing, and control operations in quick succession, while tiered conveyors supply new cardboard boxes and remove the assembled modules.

Finally, the finished modules are inspected, packaged, and shipped to construction sites worldwide for final assembly outside the cell.

Time for Your Project?

Let's talk about your automation project. I look forward to your inquiry via email or phone.

Nick Koch

CEO / Senior Automation Expert

Wild & Küpfer embraced robot-assisted automation early on and collaborated with Robotec on several systems. These projects took about 8 – 10 months from kick-off to commissioning.