Highlights

Productivity

Processes 50,000 jars per day

Flexibility

Compatible with 30 jar variants

Efficiency

Low power consumption

Safety

No manual lifting required, protected cell

Initial Situation & Goals

The delicatessen products of the Ticino company Sandro Vanini are available in stores across Europe. A targeted automation was intended to relieve employees while increasing production volumes – without displacing traditional methods.

Depalletizing the new empty goods proved ideal for automation. Until now, jars were manually transferred from pallets to the work table.

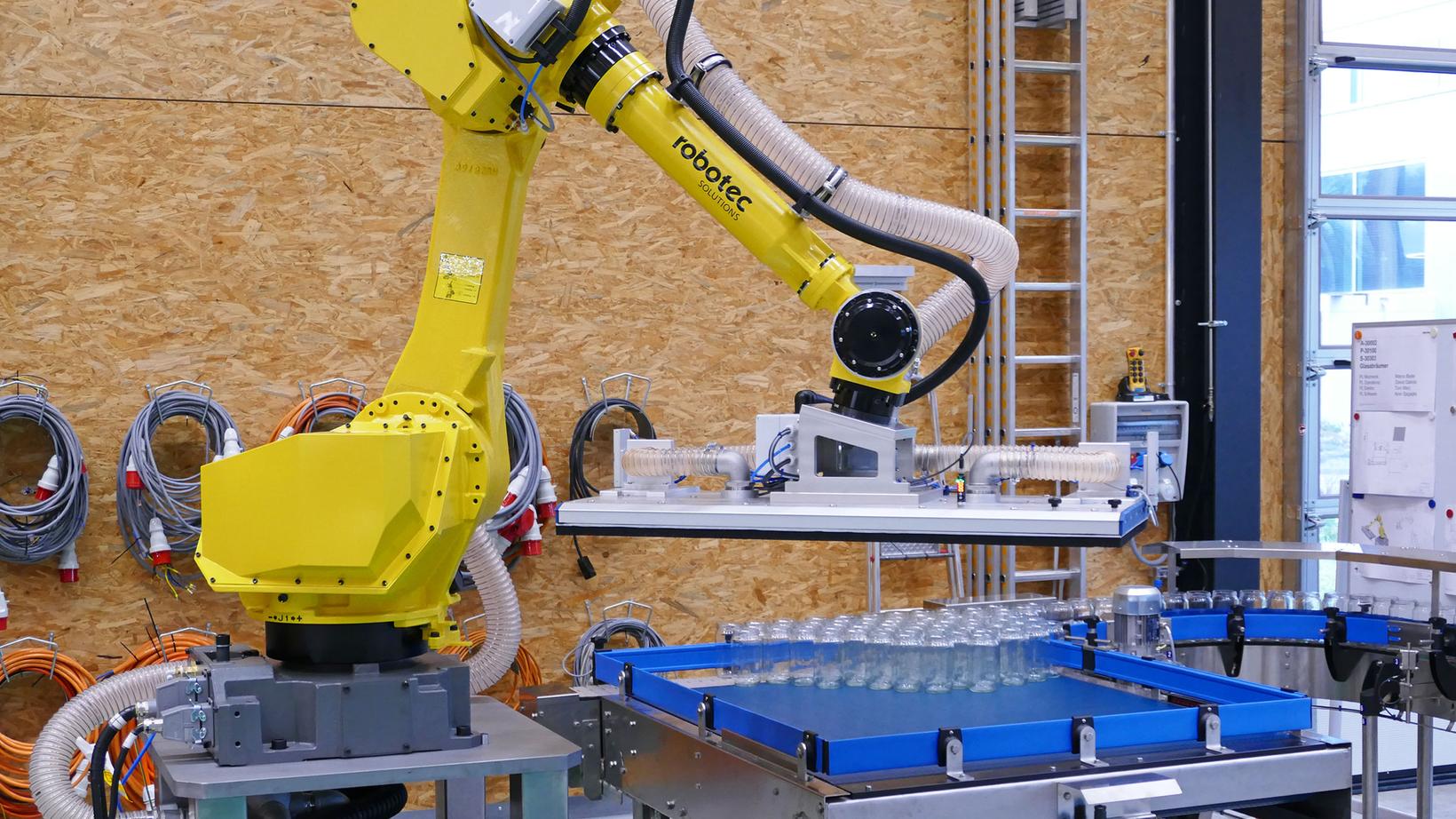

A challenge in automating this process was the variable height of the layers to be cleared: Depending on the loading height of the pallet, the jars are at ground level or up to 2 meters high. The system also had to be compatible with around 30 different jar types of varying heights.

The Solution

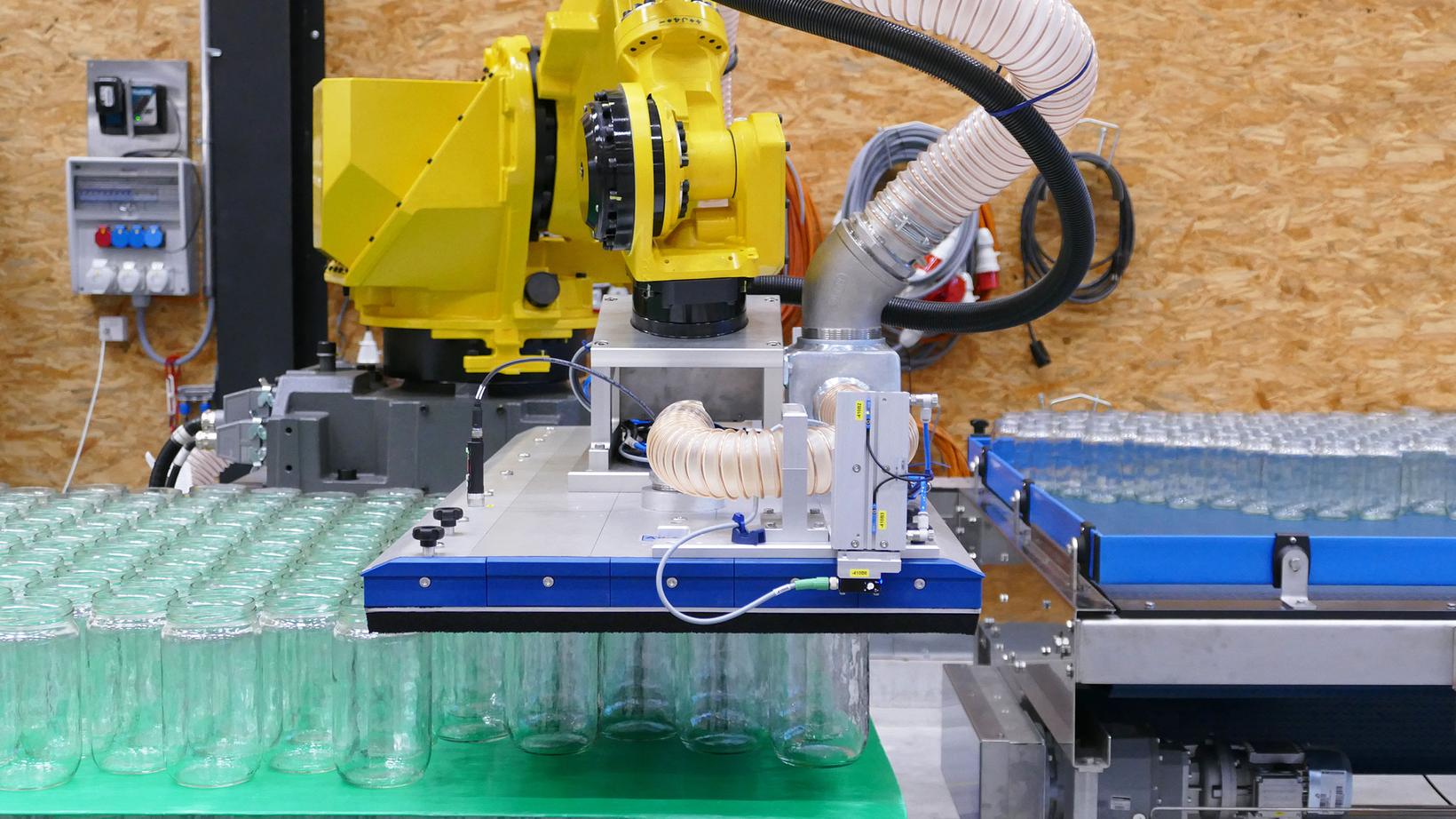

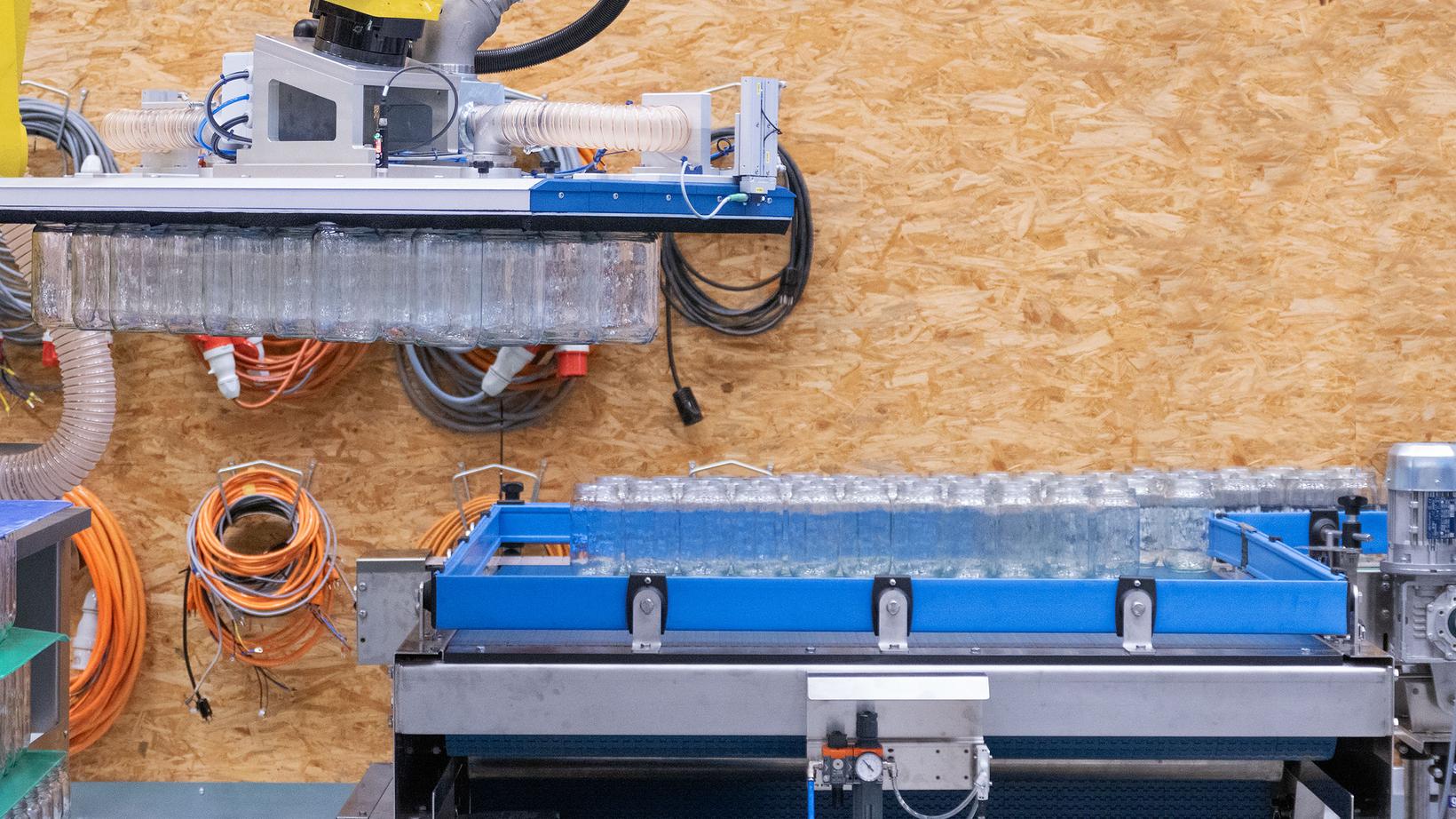

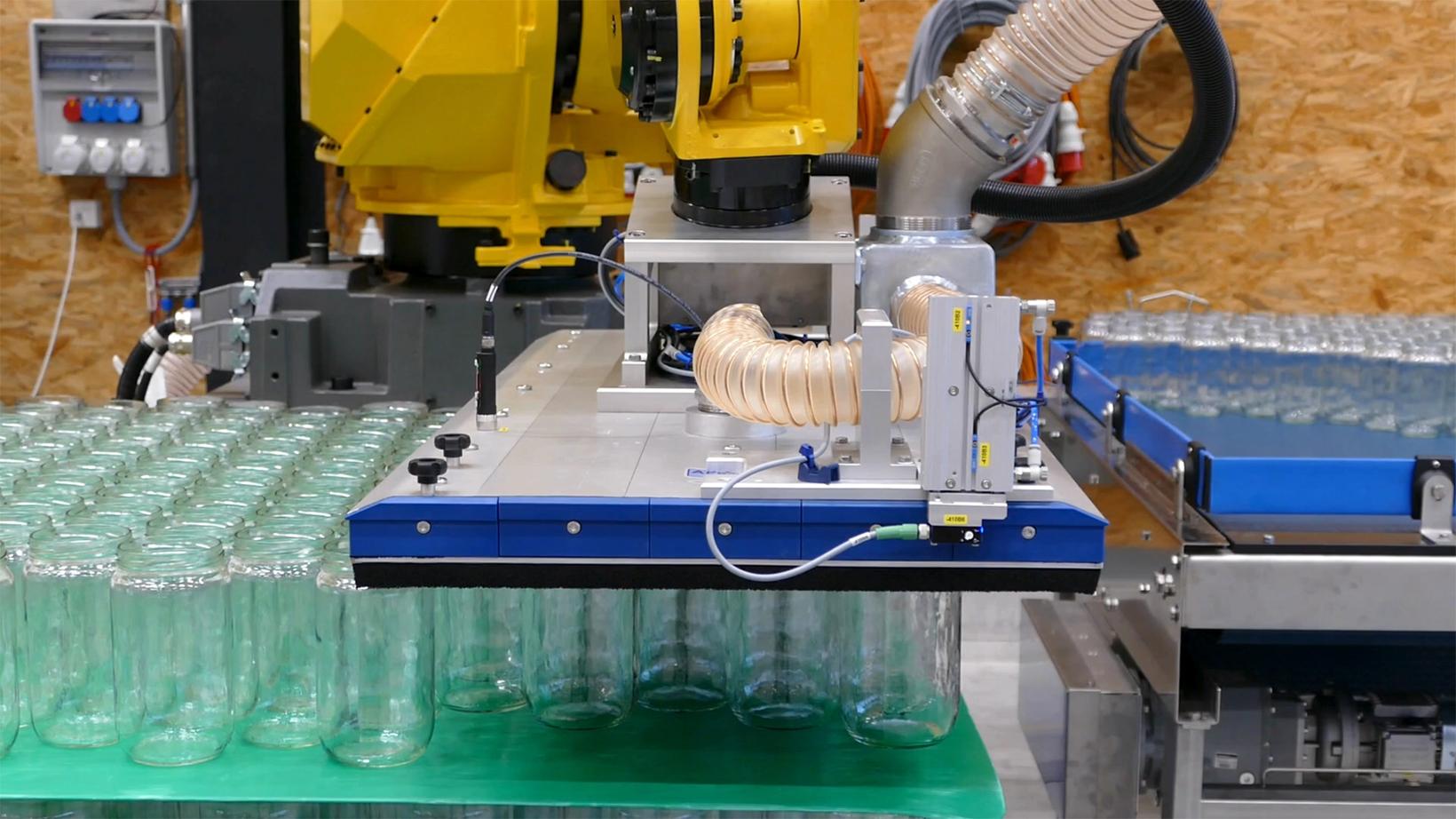

For the pick-and-place solution, we developed a suction beam with a vacuum system. Its large suction area and high suction power allow it to clear around 100 jars – about a third of the pallet surface – in one operation.

The gripper of the Robotic Cell also features a search function that uses sensors to scan the pallet height and detect the height of the jars to be cleared. The plastic intermediate layers for transport protection are also automatically removed by the gripper.

At the end of each cycle, the gripper safely places the jars on the conveyor belt leading to the filling station. The jar remover quickly proved itself in everyday work, setting initial records with over 50,000 jars per day.

Industry

Applications

Time for Your Project?

Let's talk about your automation project. I look forward to your inquiry via email or phone.

Nick Koch

CEO / Senior Automation Expert

We conducted several feasibility studies as well as test setups and test runs in-house. This ensured that the assembly and commissioning at the customer's site took only 3 days.