Highlights

Productivity

Cycle time under 12 seconds

Safety

Safety at Industry 4.0 standard

Efficiency

Automatic tray handling

Usability

Central HMI with touchscreen

Initial Situation & Goals

For the medical technology division, GEMÜ Switzerland manufactures seven different plastic parts on two injection molding machines. These should be automatically removed from the machines, subjected to a quality check, and then packed and stacked in trays.

For each injection molding cycle, 2 or 16 finished parts had to be removed and further processed – all with a cycle time of under 12 seconds.

Another challenge was to optimally utilize the tight space in the cleanroom. Due to Covid-19, the required quantities increased manifold during the project. This was mitigated during the development phase by adding an injection molding machine and two additional robots.

The Solution

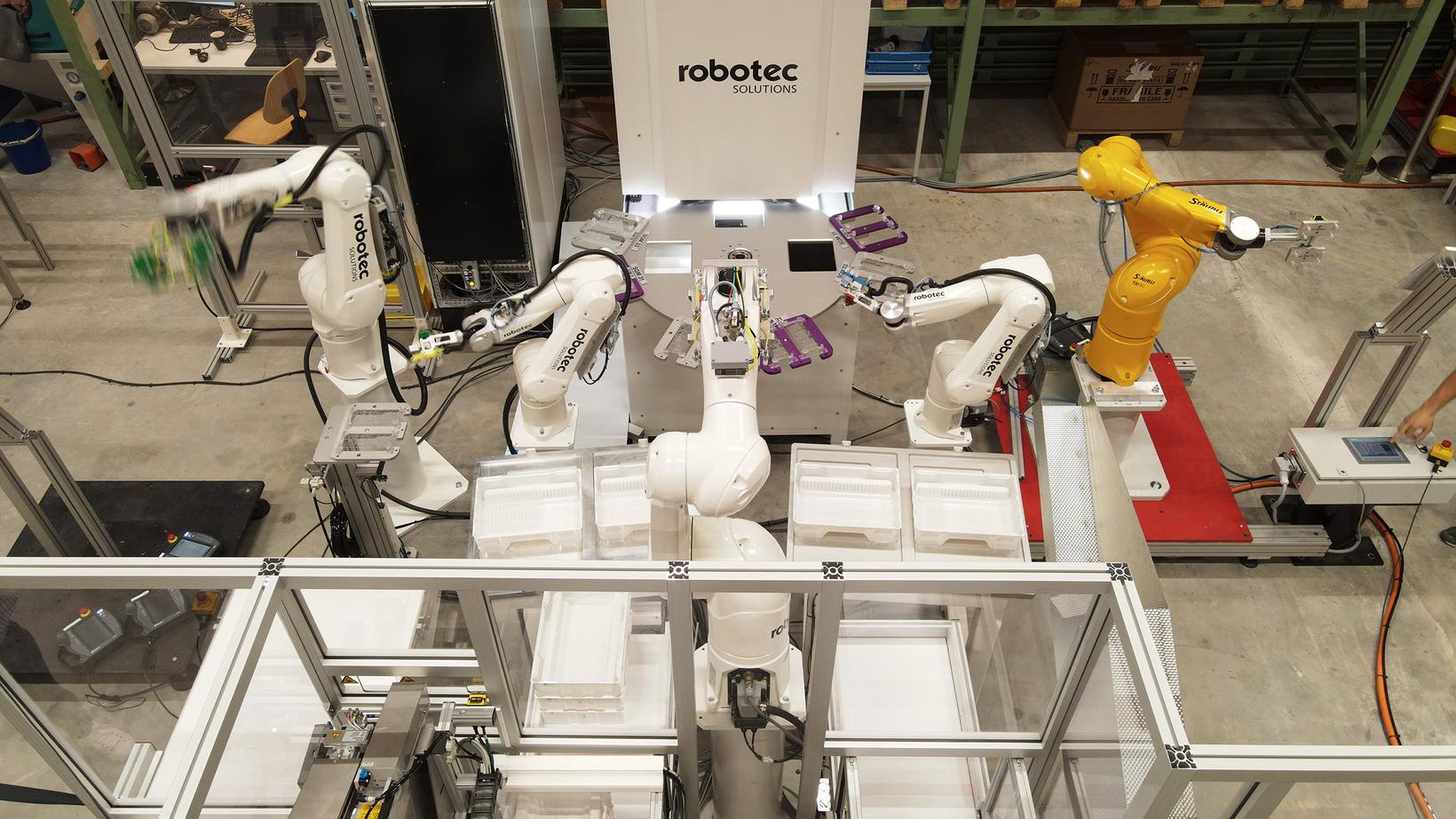

Two Robot cells with three and five robots respectively were developed in the final stage. Standardized gripper change systems, high-resolution camera inspections, an electric rotary table, cleanroom-compatible conveyors, label printers, and a sophisticated safety system at Industry 4.0 standard were combined.

Both systems can be operated via a central HMI with a large touchscreen and can be converted from one product to the next in less than ten minutes. The interchangeable parts are mechanically and color-coded and are queried via the software developed by Robotec.

This reduced the risk of errors during operation to an absolute minimum. Automatic tray handling contributes to the high autonomy of the system.

Industry

Applications

Time for your project?

Let's talk about your automation project. I look forward to your inquiry via email or phone.

Nick Koch

CEO / Senior Automation Expert

The complex requirements were successfully realized despite constantly increasing demands. Due to the short communication paths at Robotec and the high flexibility of our team, the changes could be implemented quickly and pragmatically.

Robotec projectteam

Samuel Bürkli

Head of Project Management & Mechanical Engineering

Sven Schmid

Head of Services

Marco Bader

Project Management & Mechanical Engineering

Nick Schenker

Project Management & Software Engineering

Jonas Pechlaner

Project Management & Software Engineering

Stefan Hänseler

Head of Control & Software Engineering | Deputy Managing Director