Highlights

Productivity

Autonomous 3-shift operation without operator intervention

Flexibility

Easy retooling for a different product or reference part

Efficiency

Low power consumption through the use of robots

Usability

Robotec HMI with intuitive operation via touchscreen

Initial Situation & Goals

The customer is one of the leading suppliers in the Luxury goods and watch manufacturing . For over 15 years, the company has relied on Robotec systems used in production. Due to increased market demand and new products, the customer decided to acquire additional robotic systems to ensure the required productivity in an economical and efficient manner.

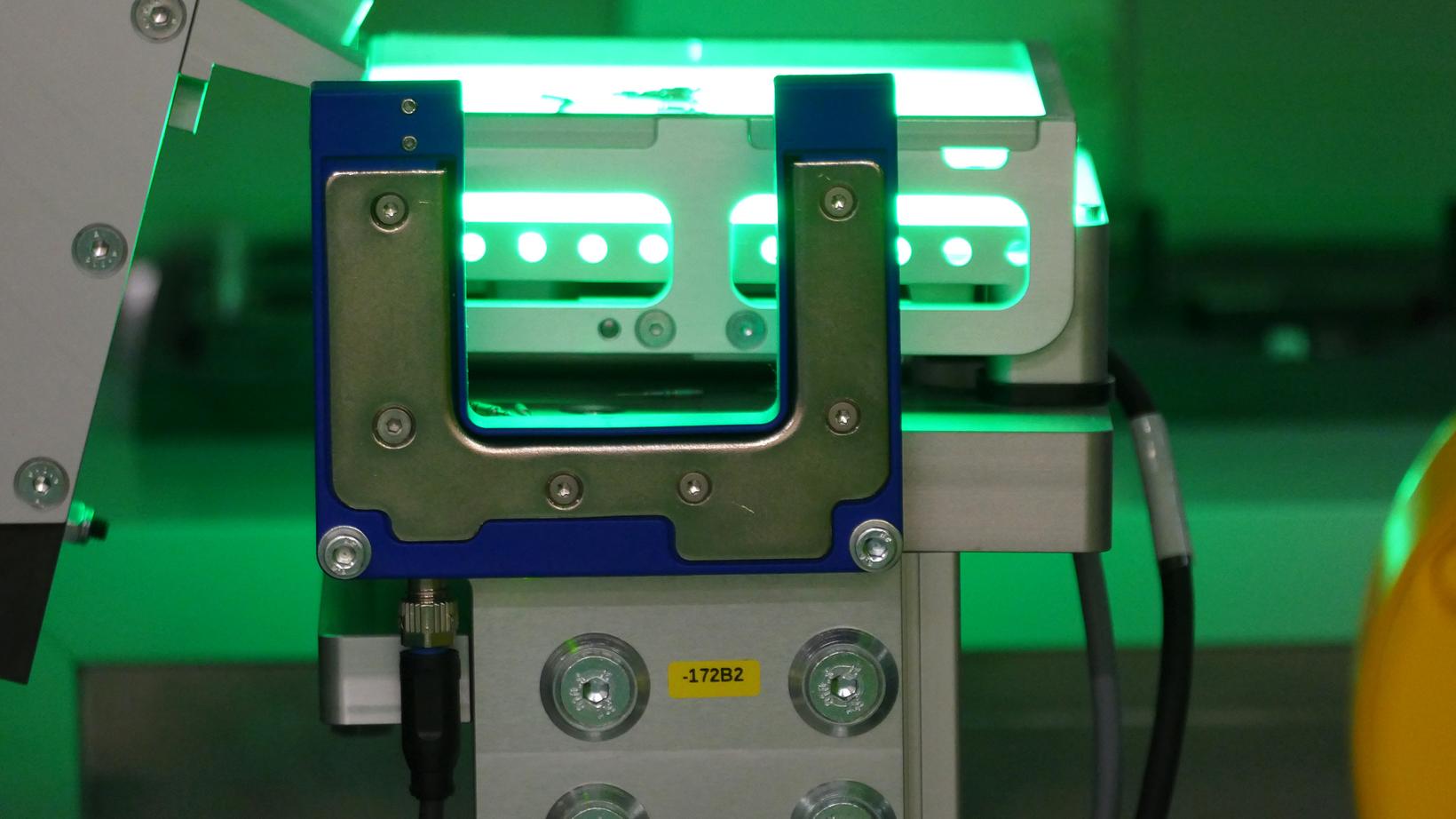

The process to be automated was the loading and unloading of an injection molding machine. Different small metal parts were to be inserted. The 4-cavity tool produces four parts every 30 seconds, which are to be removed by robots and placed according to cavities. Additionally, the sprue should also be automatically removed.

The Solution

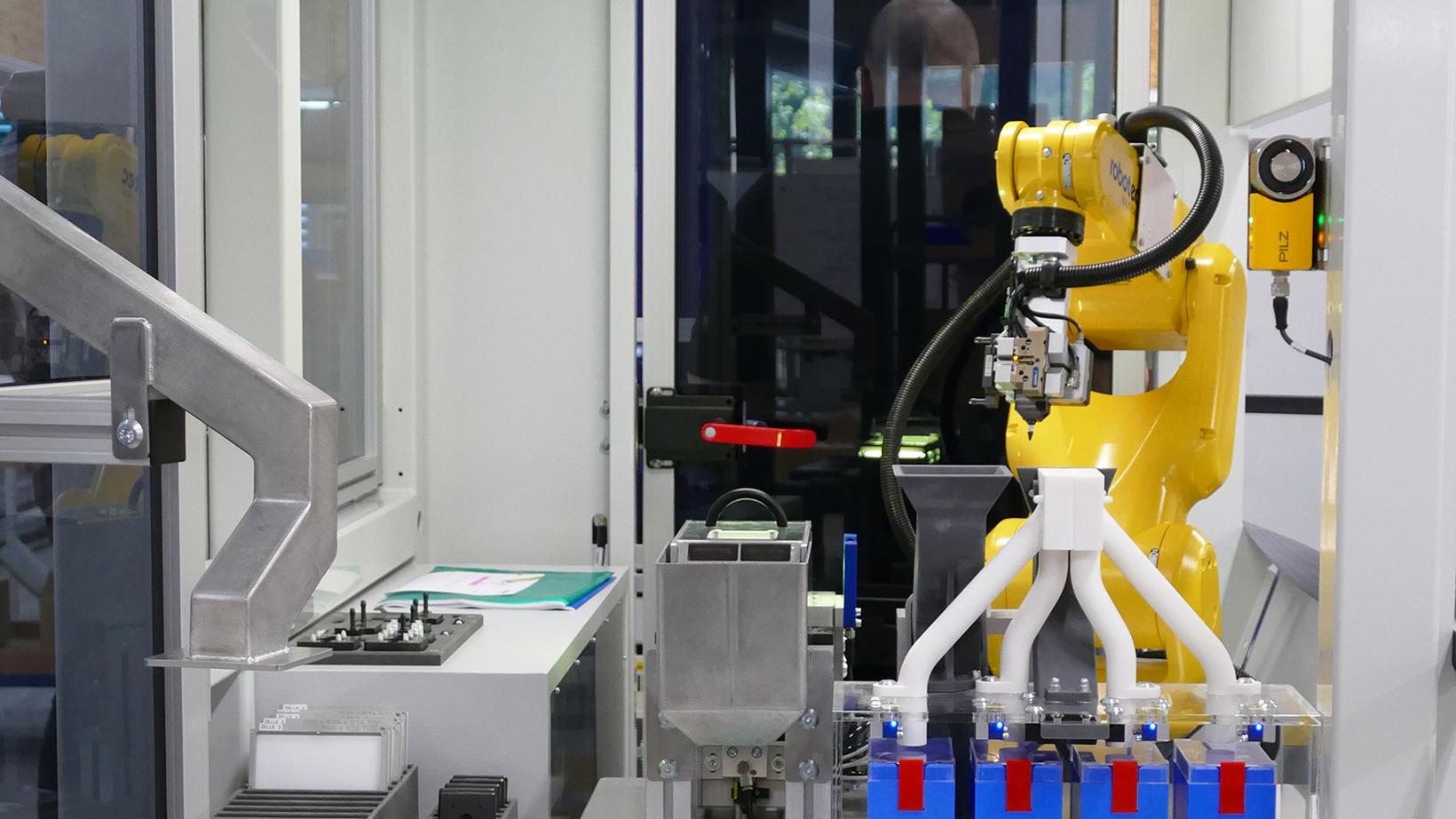

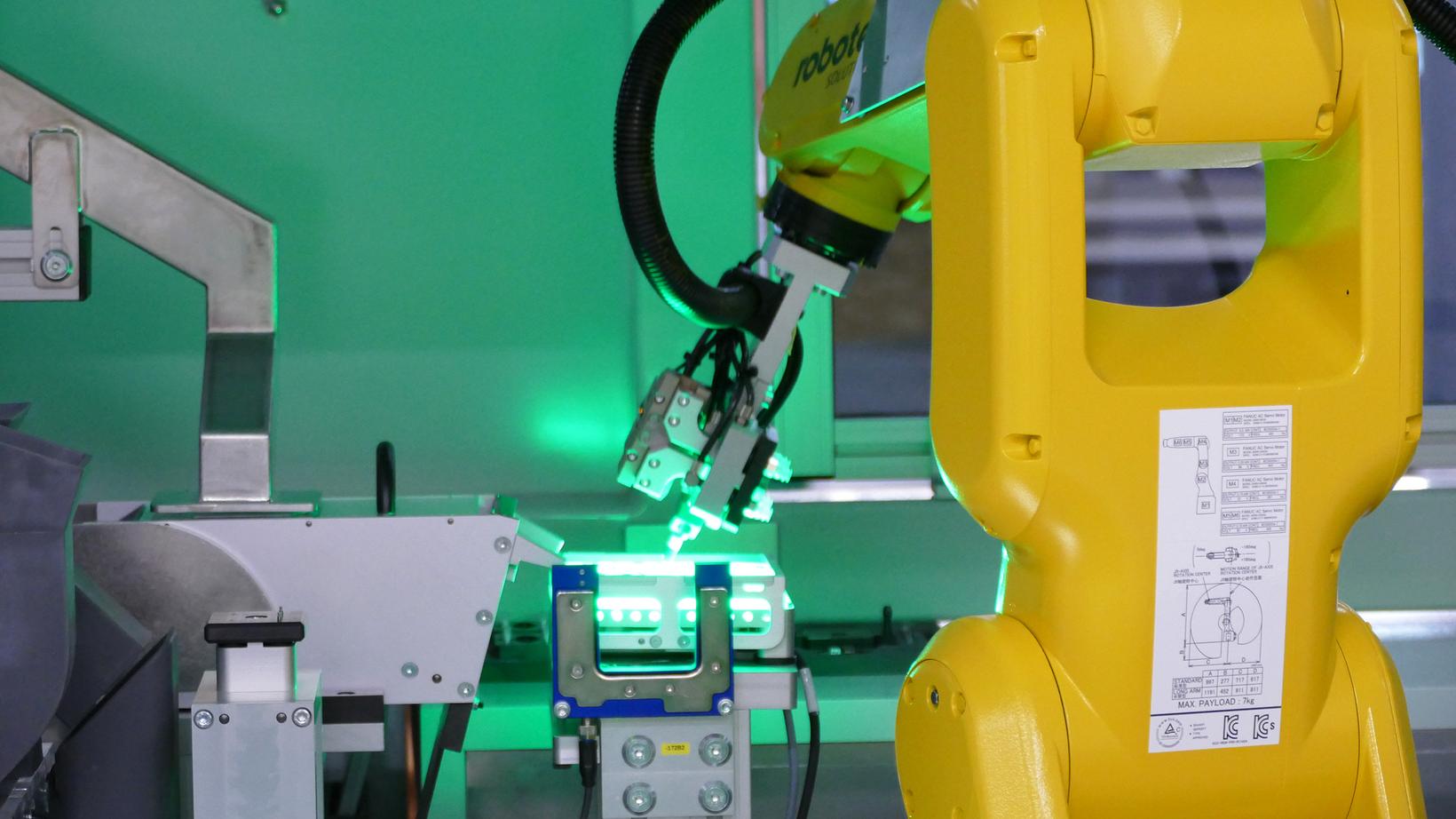

A Robotec feeder separates the raw parts. The camera of the Vision Solution determines the position and orientation of the small parts and transmits both to the Robot . This prepares the four raw parts individually, picks them up, and waits in front of the tool until it opens. The robot then removes the four finished parts and grabs the sprue. After that, it places the four raw parts in.

While the loading and unloading itself is a classic automation process, the task presented several challenges. On one hand, there was a relatively large variety of parts with seven different reference parts. On the other hand, separating the raw parts proved to be tricky as they tend to roll. A fast cycle time and 3-shift operation were additional challenges that we successfully solved.

Industry

Applications

Time for your project?

Let's talk about your automation project. I look forward to your inquiry via email or phone.

Nick Koch

CEO / Senior Automation Expert

Through our experience with robot vision grippers, we have developed a system that ensures gripping without marking the parts. This guarantees gentle handling of the delicate components.

Robotec projectteam

Roman Müller

Project Management & Software Engineering

Urs Heimann

Services

Samuel Bürkli

Head of Project Management & Mechanical Engineering

Oliver Guggisberg

Project Management & Control Engineering

Jamie Dubs

Trainee in Mechanical Engineering