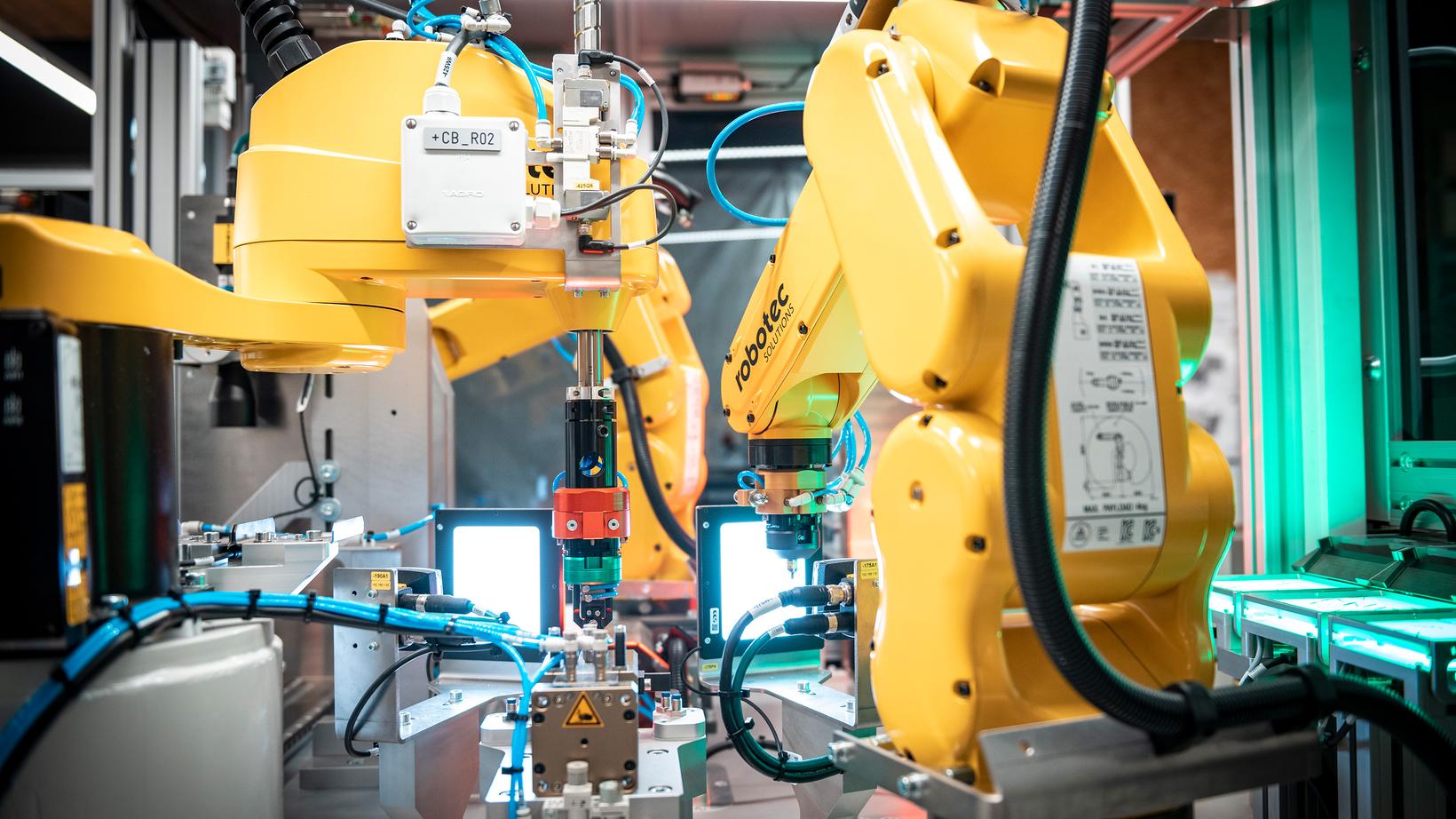

Robotec is the first and largest Swiss system integrator for FANUC robots: We combine specific industry know-how with the latest automation technology – through intelligent solutions, we enhance efficiency, quality, and competitiveness in production and manufacturing.

As a leading integrator of FANUC robots in Switzerland, Robotec supports companies from various industries in automating production and manufacturing processes:

Plastics

In the Plastics processing , FANUC robots impress with precision and repeatability – crucial for complex molded parts and high-volume production lines.

- Efficient automation of injection molding processes

- Reliable demolding, packaging, and handling

- Consistent product quality at high volumes

Electronics & Semiconductors

In the Electronics and semiconductor industry , precision, cleanliness, and efficiency are crucial. FANUC robots enable highly accurate processes and are perfect for sensitive production environments.

- Precise handling of sensitive components and wafers

- Automated assembly, mounting, and testing processes

- Cleanroom-compatible solutions for the highest quality standards

Medtech and Pharma

The Medtech and pharmaceutical industry requires the highest precision, cleanroom compatibility, and traceability – strengths that FANUC robots ideally fulfill.

- Automated assembly of the smallest components

- Hygienic production processes with high safety

- Seamless process documentation for regulatory requirements

Metal Industry

In the Metal industry , FANUC robots are proven partners for robust applications and continuous operation.

- Precise welding with consistent quality

- Flexible handling of heavy workpieces

- High durability for 24/7 automation

Food Industry

In the Food production , FANUC robots also increase efficiency and safety.

- Hygienic processing and packaging

- Reduction of manual, repetitive tasks

- Compliance with strict quality and safety standards

Experience from 1000 FANUC Robots

Since 1997, FANUC has maintained a close partnership with Robotec in Seon: as the official system house for Switzerland focusing on robot system construction. In 2010, we were awarded the FANUC Robotics Award as the best system house. And by 2013, we celebrated the 500th commissioning of a FANUC robot together. We have now integrated over 1000 FANUC robots worldwide – a unique success story in Robotec green and FANUC yellow.

Why FANUC Robots?

FANUC robots are world leaders in industrial automation and offer Swiss companies the highest reliability and flexibility. With Robotec as a system integrator, you benefit from the latest technology, practical experience, and a strong local partner.

- The largest robot portfolio worldwide – from small part handling to heavy-duty

- High reliability, low failure rates, and long service life

- Energy-efficient systems with minimal maintenance

- Global service and spare parts supply

- 20 years guaranteed availability of spare parts

About FANUC

FANUC is a global technology leader and pioneer in automation, known for highly reliable industrial robots and CNC controls. For nearly 30 years, we have maintained a close partnership with FANUC and together delight our customers.

Cases

Customer Projects with FANUC Robots

CNC Machining with Automatic Tool Change in Record Time

Autonomous CNC Machining in Luxury Goods Manufacturing

Depalletizing New Empty Containers with Vacuum Gripper

Assembly of Modules with Three Robots and Vision Systems

Palletizing Chilled Salad Dressing Bottles

Fully Automatic Palletizing of Jam Cartons

Manufacturing of Hip Implants with Powerful Robot Cell

Loading and Unloading an Injection Molding Machine in 3-Shift Operation

With Robotec and FANUC, we have found the ideal combination: a perfectly integrated automation solution that reduces our production costs and increases quality. We were particularly impressed by the reliability of the FANUC robots – they have been running smoothly in 24/7 operation since installation.

Now rely on FANUC with Robotec

Start your automation project with FANUC robots now: from a single robot cell to an intelligent, fully automated production facility. Call or email to schedule a Teams call. I look forward to hearing from you.