Solutions for Your Industry

Automation in Pharma and Medtech Production

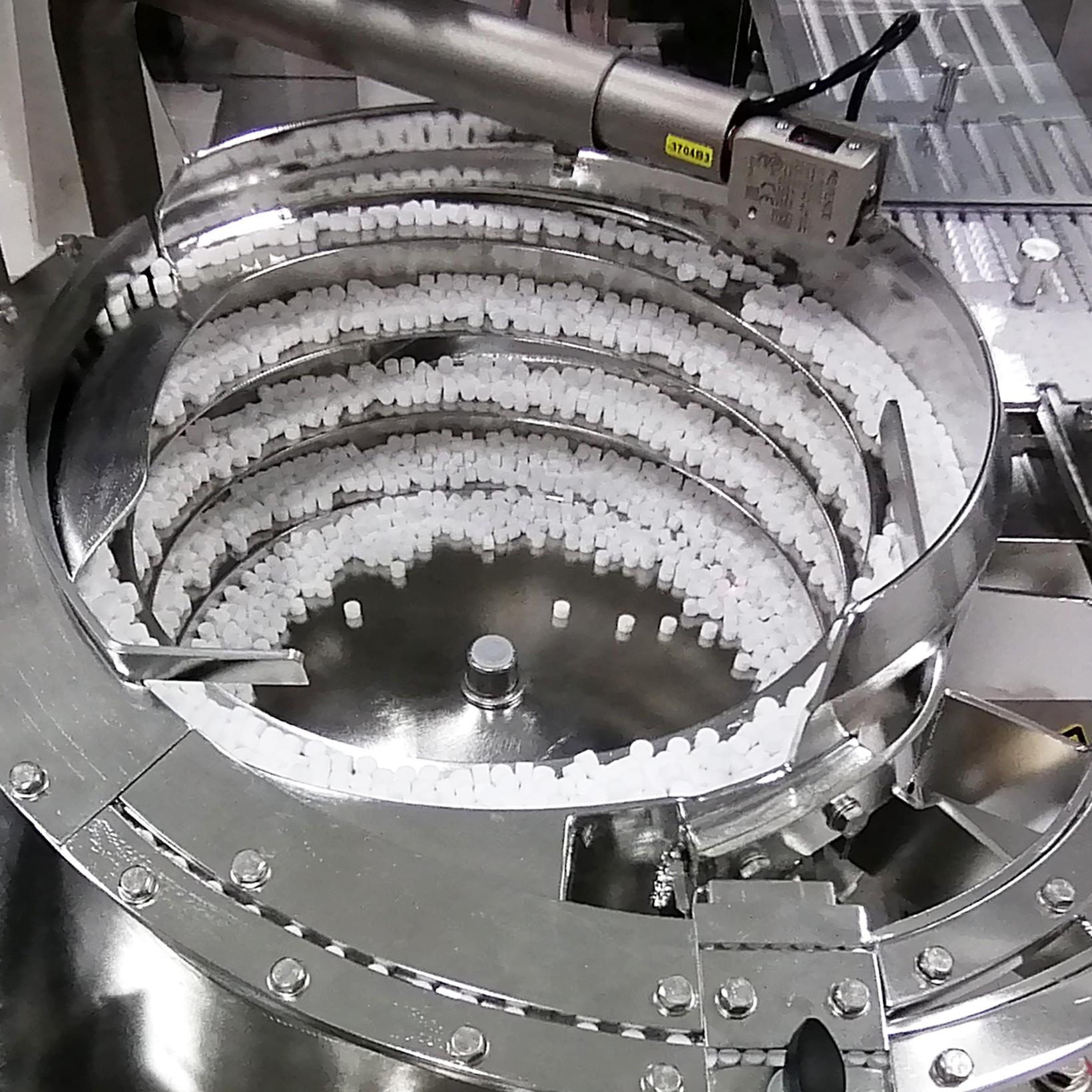

In pharma and medtech production, the highest standards of precision, hygiene, and traceability are required. With our automation solutions, we support you in implementing compliant processes safely and efficiently.

The production of medical devices and pharmaceutical components is subject to strict regulatory requirements, such as GMP, GAMP, and ISO standards. Processes must be precisely documented, fully traceable, and always auditable. At the same time, the highest standards of sterility, hygiene, and the cleaning of surfaces and edges apply. Every material that comes into contact with the product must be certified.

In injection molding and downstream processing, handling the finest parts requires absolute precision—often beyond what is reliably possible manually. The zero-error tolerance applies: Every single item must be inspected and documented. Additionally, the aim is to reduce human influence as much as possible to minimize the risk of bacterial contamination.

Advantages of Automation

- GAMP and GMP-compliant automation for regulated production environments

- Reproducible, validatable processes with a complete audit trail

- Traceability of every single component through comprehensive data capture

- Cleanroom-compatible solutions up to ISO Class 5

- Contactless, sterile handling to minimize bacterial risks

- Precision in the micrometer range, even for complex injection molding components

- 100% inline inspection of each part with documented error detection

- Multiple processes can be integrated into one system: from unpacking to loading and unloading, quality check, assembly, and applying stickers

With this system, we were able to increase the production volume of hip implants by 45%. The modular concept also ensures flexibility in use and allows for easy cleaning.

Why Robotec

Our 5-Point Promise

Frequently Asked Questions (FAQ)

Your Contact Person