Robot Cells and Lines

With robot cells or entire lines, we automate complex processes in production and manufacturing. We take on any challenge and develop customized partial or complete systems for industrial clients.

Flexibility is often at the top of the requirements list for automation projects today – alongside basics such as increased productivity or process reliability. We see ourselves as a creative sparring partner for automation and accompany industrial customers from the first inquiry to commissioning and beyond.

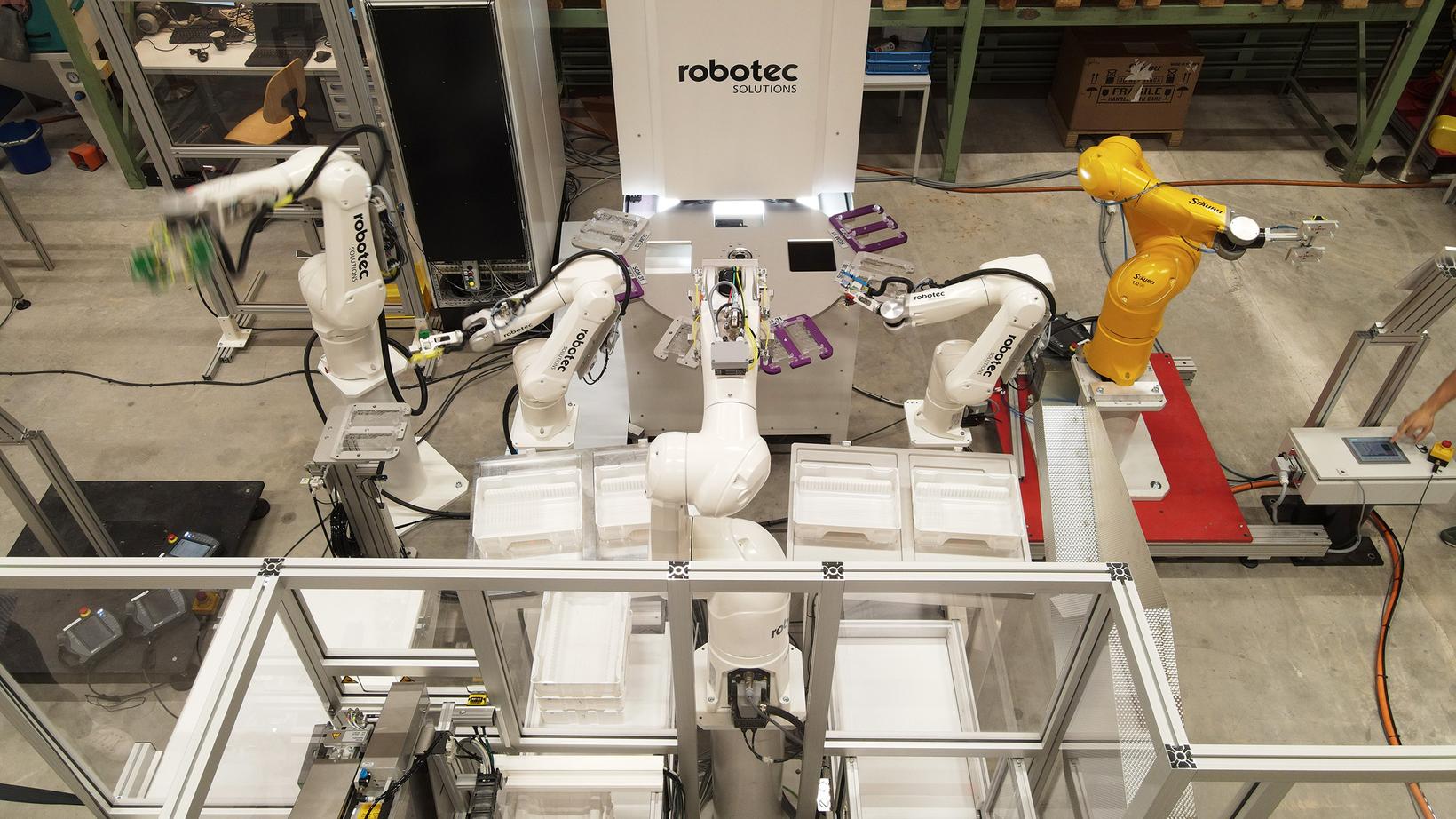

From Single to Multi-Robot Systems

Our automation solutions are tailored to the requirements of each project: We develop new systems for existing production. Or we realize comprehensive production lines or custom robot cells – whether as a single-robot system or complex multi-robot solutions with machining centers.

At a Glance

Simple to Complex

- Pre-configured standard cells

- Custom-developed complete solutions

- Single-robot or multi-robot systems

- Integration of cobots or mobile robots

- Complex manufacturing islands and production lines

Solutions for Every Goal

- Small or large batch sizes (starting from batch size 1)

- High Mix / Low Volume

- Flexibility in quantities and expansions

- Reduce scrap rate

- Quick retooling

Individual Cooperation

- Developing and implementing subsystems

- Realizing complete solutions as a general contractor

- Adjustments and upgrades of existing systems

- Cycle time analyses and feasibility studies

Our Partners

Cognex

Cognex is a leading global provider of industrial image processing systems. We have been a certified Cognex partner since 2022 and maintain a close knowledge exchange that brings together the strengths of both companies.

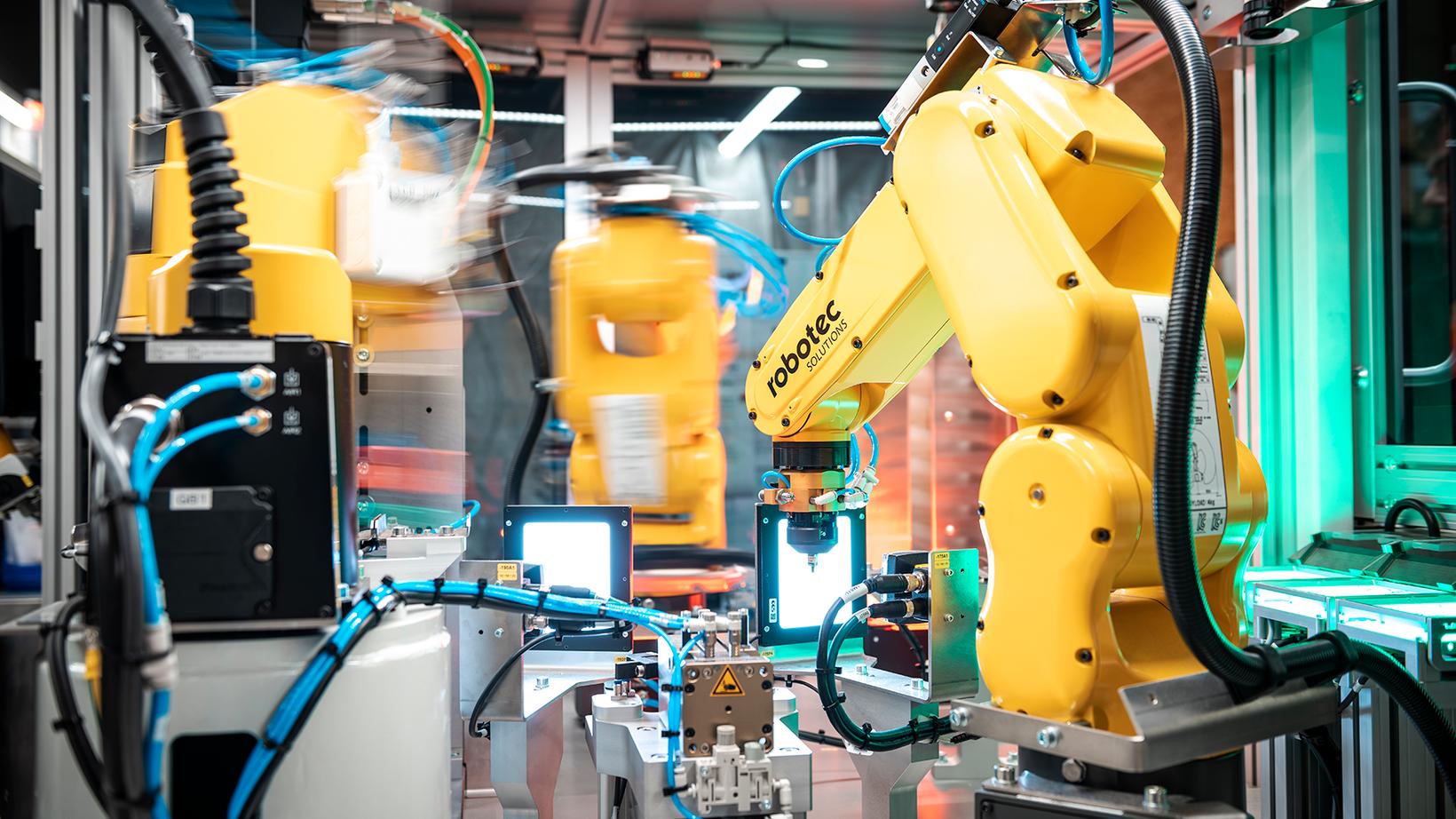

Stäubli Robotics

Stäubli Robotics is a leading global supplier of high-quality industrial robots. Since 2017, we have been a certified partner of this innovative Swiss company, whose systems are valued for their speed, reliability, and flexibility.

Why Robotec

Our 5-Point Promise

Customer Projects with Robot Cells

Autonomous CNC Machining in Luxury Goods Manufacturing

CNC Machining with Automatic Tool Change in Record Time

Depalletizing New Empty Containers with Vacuum Gripper

Assembly of Modules with Three Robots and Vision Systems

Palletizing Chilled Salad Dressing Bottles

Aseptic Handling of Powder Containers in Isolator

Injection Molding Removal in Clean Room with Quality Inspection

Precise Pick-and-Place of Chocolate Pralines

Fully Automatic Palletizing of Jam Cartons

Frequently Asked Questions

Your Contact Person