Highlights

Productivity

8 hours of autonomous operation

Flexibility

Quickly exchangeable grippers

Efficiency

Automatic alignment of parts

Usability

Robotec HMI with PC touchscreen

Initial Situation & Goals

A renowned client from the luxury goods industry wanted to automate the CNC machining of certain components. They were looking for a flexible and precise solution that could process different parts in medium and large series completely autonomously: The system should be able to produce independently during a full production shift (8 hours).

The goals of the automation solution were to increase productivity, enhance production autonomy, and enable faster series changes. Since the parts are in the luxury goods segment, manufacturing quality was also a central criterion. Particularly during gripping and machining operations, the components must not be damaged.

The Solution

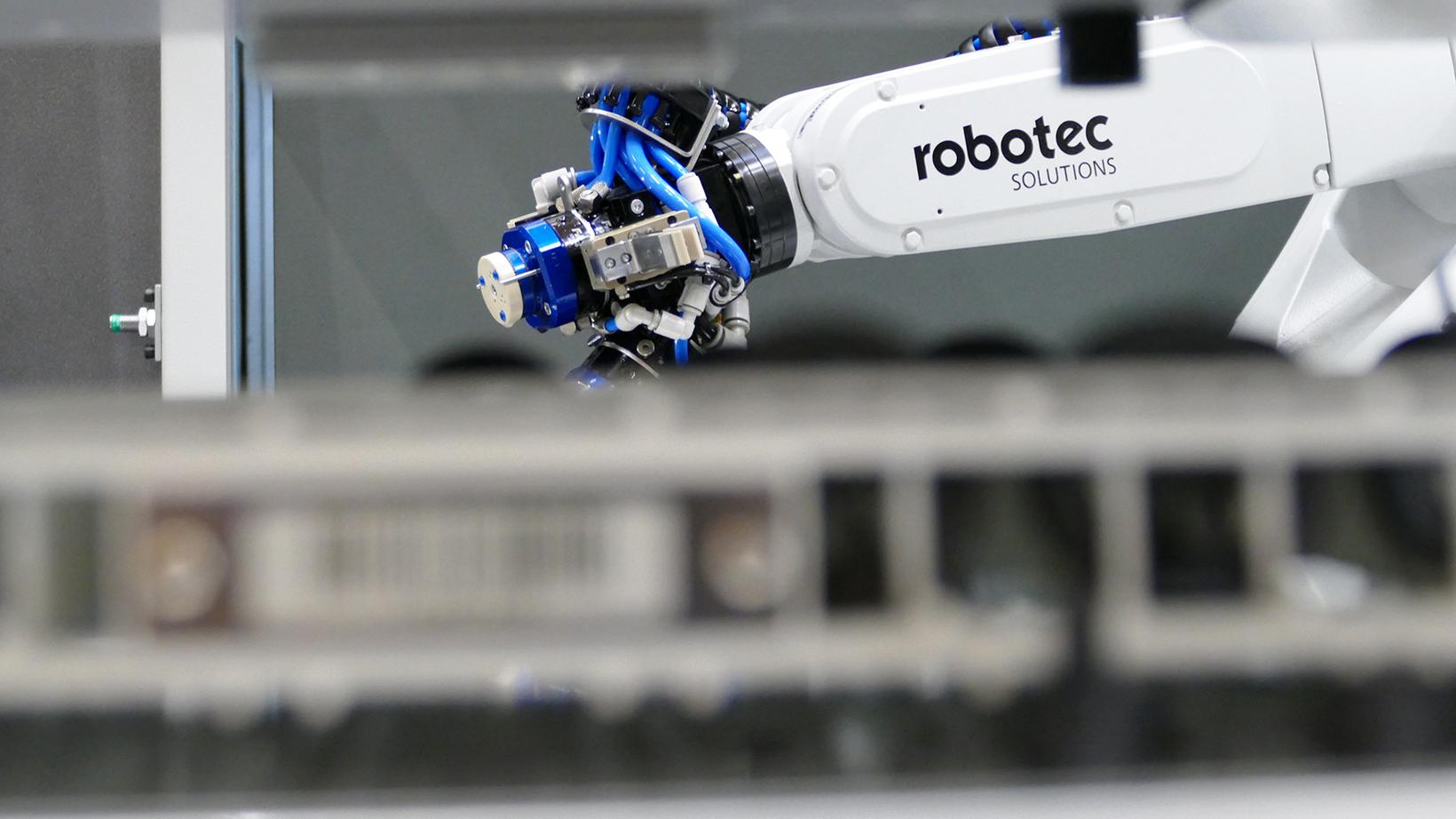

The robotic system consists of two main elements: a vertical CNC machining center (FANUC Robodrill) and a Robotec Robot Cell that ensures the loading of raw parts and the unloading of finished parts. The machining center has a double clamping device, allowing quick changes between component families.

The robot cell consists of a drawer magazine that enables up to 8 hours of autonomy. The magazine can hold 10 baskets of raw parts and 10 baskets of machined parts. An automated device removes the baskets with the parts to be processed from the magazine and moves them inside the robot cell. A sliding cylinder system tilts the baskets so that the parts are correctly positioned in their holders for the robot.

A FANUC multi-joint robot with a multifunctional gripper developed by Robotec then uses a parallel gripper to pick a raw part from the basket and place it on a backlit table. A Vision System with an intelligent Cognex IN-Sight camera checks the alignment of the part. If it is misaligned, it is turned in a special station. The robot adjusts the angular alignment accordingly and picks the part with a vacuum gripper.

The gripper has a common base for all references and quickly exchangeable grippers with different form parts. The human-machine interface of the robot cell features a PC touchscreen according to Robotec standards, while the HMI of the Robodrill milling machine is based on FANUC standards.

Industry

Applications

Time for Your Project?

Let's talk about your automation project. I look forward to your inquiry via email or phone.

Nick Koch

CEO / Senior Automation Expert

Through our experience with robot vision grippers, we have developed a system that ensures gripping without marking the parts, guaranteeing gentle handling of delicate components.

Robotec projectteam

Gwenölé Bergeon

Senior Automation Expert Romandie

Kevin Bossard

Project Management & Mechanical Engineering

Simon Rüdiger

Project Management & Software Engineering

Roman Müller

Project Management & Software Engineering

Oliver Guggisberg

Project Management & Control Engineering

Urs Heimann

Services